How Dock Levelers Improve Loading Dock Safety and Productivity

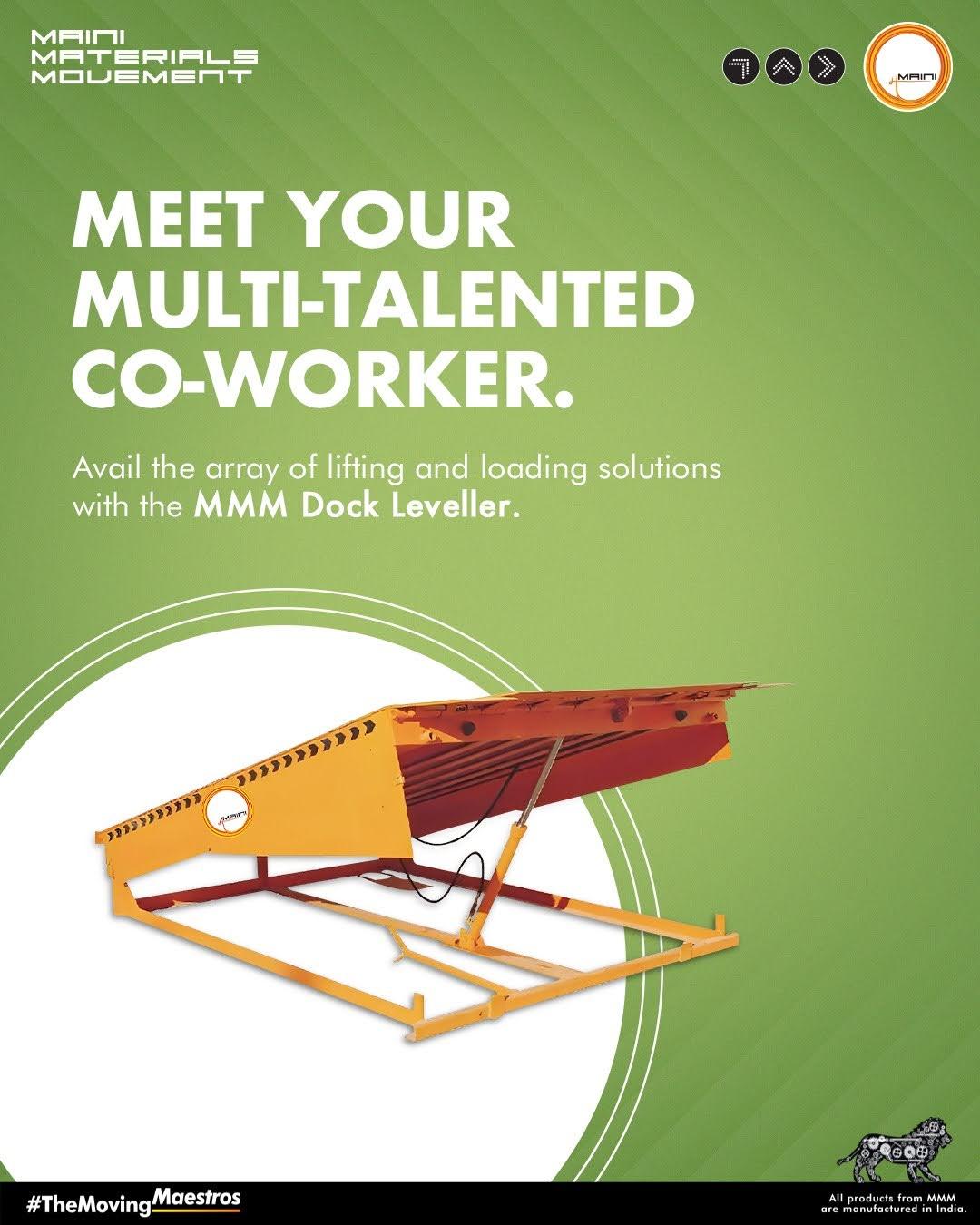

In a fast-paced warehouse environment, efficiency and safety go hand in hand. Nowhere is this more apparent than at the loading dock—where speed, precision, and secure handling are non-negotiable. One key component that has revolutionized both performance and protection at this critical point is the dock leveller. With advanced solutions from trusted brands like Maini Materials Movement, operations are smoother, safer, and more productive.

The Role of Dock Levelers in Modern Warehousing

A dock leveler bridges the gap between a truck bed and the warehouse floor. Without it, forklifts and pallet jacks would face unstable or uneven transitions, increasing the risk of accidents, damage, or downtime.

Here's what dock levelers achieve:

-

Safe access for loading and unloading equipment

-

Reduced manual handling errors

-

Protection from trailer height differences

-

Smooth transition from dock to truck bed

This simple yet powerful device plays a crucial role in managing height variation and minimizing the physical strain on workers.

Benefits of Dock Levelers for Safety and Productivity

Enhanced Safety for Dock Workers

Slips, trips, and falls are among the most common warehouse injuries. Dock levelers help create a stable, even surface for forklifts and other machinery to move across.

Safety Features Include:

-

Anti-slip surface

-

Lip control for secure placement

-

Safety legs for controlled movement

-

Emergency stop features on hydraulic models

By reducing the need for risky maneuvers or adjustments, dock levelers help keep employees safe.

Improved Workflow Efficiency

Every minute saved at the loading dock contributes to overall warehouse performance. Dock levelers ensure that trucks can be loaded and unloaded quickly without waiting for additional equipment adjustments.

Efficiency Boosters:

-

Faster turnaround times

-

Seamless transition between dock and trailer

-

Reduced product damage during transfer

-

Supports high-volume loading operations

Integrating dock levelers in warehouse workflows means faster, more consistent shipping cycles with fewer interruptions.

Choosing the Right Type of Dock Leveler

There’s no one-size-fits-all when it comes to dock equipment. Warehouses have different requirements based on load types, dock heights, and operational volume.

Common Types of Dock Levelers:

-

Hydraulic Dock Levelers – Automatically operated for quick, low-effort use.

-

Mechanical Dock Levelers – Operated with manual effort, ideal for lighter use.

-

Air-Powered Dock Levelers – Uses air-powered technology, offering a middle ground between hydraulic and mechanical.

-

Vertical Dock Levelers – Great for temperature-sensitive environments, reducing energy loss.

Maini Materials Movement offers a wide range of levelers suited for diverse warehousing needs.

Integrating Dock Lifts for Greater Flexibility

While dock levelers help adjust for trailer height, dock lifts take it a step further by enabling height adjustments across a broader range. This is especially useful when there’s a mismatch in dock height and vehicle bed levels.

Why Use Dock Lifts?

-

Handle non-standard trucks or vans

-

Allow ground-level loading

-

Improve ergonomics and reduce strain

-

Adaptable to varying warehouse structures

A combination of dock lifts and levelers ensures full coverage across different loading scenarios, helping to streamline your operations and reduce logistical headaches.

Key Advantages of Dock Equipment Automation

Automated dock systems do more than just reduce labor. They allow real-time monitoring and intelligent control of dock operations. When paired with smart sensors or software, dock levelers and lifts can offer:

-

Load monitoring and diagnostics

-

Safer deployment via automatic locking systems

-

Alerts for improper equipment use

-

Data collection for productivity analysis

Smart automation tools are helping warehouses gain better control, reduce risks, and maintain tighter shipping schedules.

Best Practices for Using Dock Levelers Effectively

Proper usage and regular maintenance are essential for keeping dock equipment in top shape. Here are some essential tips:

Do’s:

-

Perform daily visual checks for wear and tear

-

Train workers on proper operation techniques

-

Lubricate moving parts regularly

-

Use wheel chocks or vehicle restraints during loading

-

Schedule routine inspections by certified professionals

Don’ts:

-

Don’t exceed the weight capacity of the leveler

-

Don’t ignore unusual noises or misalignment

-

Don’t let debris accumulate under or around the equipment

-

Don’t bypass safety features or override controls

By following these practices, you can extend equipment life while maintaining high safety standards.

Conclusion: Smarter Docks Start with Smarter Equipment

The loading dock is a vital intersection of productivity and safety in any warehouse. Investing in a dock leveler, along with dock lifts, can dramatically improve the efficiency of your operations while protecting workers from avoidable injuries.

Maini Materials Movement provides robust, industrial-grade solutions that integrate seamlessly into modern warehousing environments. With the right tools and smart planning, your facility can boost throughput, reduce downtime, and operate with confidence.

So, the next time you evaluate your dock operations, remember—the smallest gap between the dock and truck can create the biggest obstacle. With the right dock equipment, you turn that gap into an opportunity for safer, faster, and smarter logistics.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness