Carbon Brushes for DC Motors: A Key Component Behind Reliable Motor Performance

Carbon brushes for DC motors are fundamental components that keep power flowing in countless machines and devices. While they may appear simple, these small parts are critical to ensuring motors run smoothly and efficiently. From industrial machinery to portable tools, carbon brushes provide the connection that drives performance.

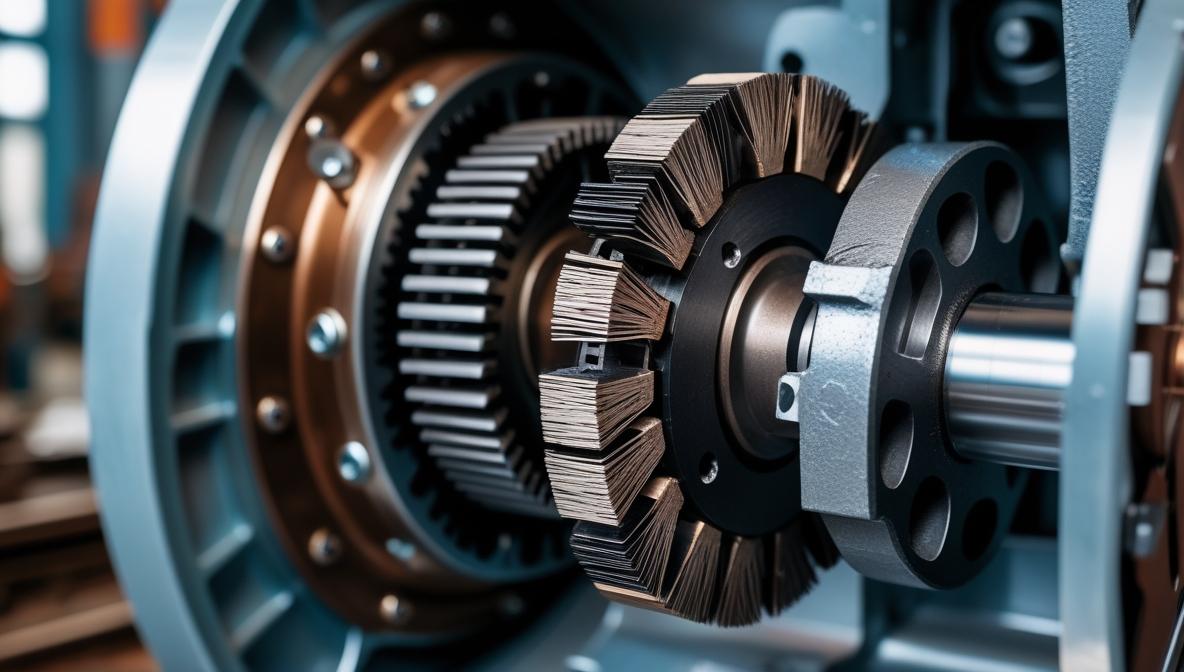

What Are Carbon Brushes and How Do They Work?

Carbon brushes are solid conductive elements that transfer electrical current from a stationary power source to the rotating part (commutator) of a DC motor. As the motor spins, the brushes maintain constant contact, enabling the circuit to stay complete and the motor to generate motion.

Because carbon is naturally self-lubricating and heat-resistant, these brushes reduce friction, prevent damage, and help the motor run longer without frequent maintenance.

Common Types of Carbon Brushes

There’s no one-size-fits-all when it comes to carbon brushes. Here are a few common types used in DC motor applications:

-

Carbon-Graphite Brushes – Ideal for standard-duty motors

-

Metal-Graphite Brushes – Suitable for low-voltage, high-current environments

-

Electrographite Brushes – Perfect for high-speed or demanding applications

-

Resin-Bonded Brushes – Often used in compact devices or light-duty motors

The correct type depends on the application’s speed, voltage, load, and operating conditions.

When Should Carbon Brushes Be Replaced?

Brushes wear down with use. Ignoring them can lead to reduced motor performance or permanent damage. Key signs include:

-

Fluctuating power or weak motor output

-

Excessive sparking at the commutator

-

Abnormal noise or vibrations

-

Visible wear beyond the acceptable limit

Timely replacement ensures the motor runs at optimal efficiency.

Selecting the Right Brush for the Job

To choose the best carbon brushes for DC motors, consider:

-

The motor’s size and speed

-

Environmental conditions (humidity, dust, heat)

-

Current and voltage requirements

-

Load and usage cycle

Matching brush specifications to the motor’s demands helps ensure long-lasting and reliable operation.

Industrial and Everyday Uses

Carbon brushes are used across a wide spectrum of industries and products, such as:

-

Automotive – Electric windows, wipers, and starter motors

-

Power Tools – Drills, grinders, and sanders

-

Industrial Machines – Conveyors, elevators, and robotics

-

Public Transport – Traction motors in electric buses and trains

-

Energy Sector – Wind turbine motors and battery-operated systems

Their versatility and reliability make them indispensable in both heavy-duty and consumer-grade equipment.

Conclusion

Carbon brushes for DC motors may be modest in appearance, but their function is vital. They ensure motors receive the power they need to operate smoothly, efficiently, and safely. By selecting the right type of brush and monitoring its condition, users can dramatically improve the performance and life span of their motor systems.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness