What Sets a Turned Parts Manufacturer Apart in High-Tolerance Production

A person who makes turned parts is getting more and more important in the areas of high-performance production and precision engineering. A lot of different industries need high-tolerance parts that work well and consistently. These industries include aerospace, medical devices, automobiles, the military, and telecommunications. In this case, not every maker is the same. A normal machine shop and a top-notch shop that makes turned parts are very different. It could mean the difference between a product working as planned and breaking down in the real world.

In the world of high-tolerance manufacturing, what makes a good turned parts manufacturer stand out? Let's look at the traits, technology, and skills that make them so.

1. Engineering skills with a high level of accuracy and flexibility

High-tolerance production means that parts can be made that are very accurate in terms of their size, usually within a few microns. This level of consistency is only possible with an expert turned parts maker, and they can keep it up over long production runs.

In some areas, like surgery or airplane fuel injector valves, even the smallest difference can make a product fail. This is why these margins are so important. These goals are met by the best producers who spend a lot of money on top-of-the-line tools, methods for checking quality, and skilled workers.

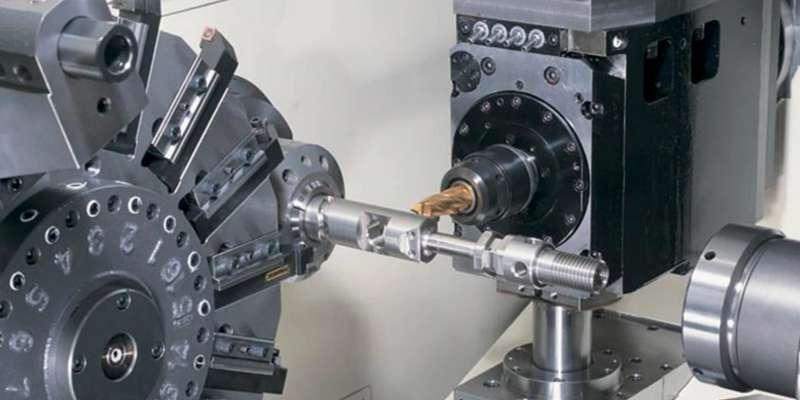

Advanced Machinery: What Swiss Machining Does One of the most important things that makes a great company that makes turned parts stand out is Swiss machining. The first things that were made with Swiss machining were parts for watches. Since then, it has become one of the best ways to make very accurate turned parts, especially ones that are small, difficult, or long.

Lathes and Swiss tools don't work the same way. The part doesn't bend because a guide screw keeps it close to the cutting tool. This lets the cutting tool cut very precisely. Because of the following, this method is great for making things with tight tolerances:

-

Much better centering

-

More exact measurements

-

Cycle times that go faster

-

It's possible for more than one tool to work at once.

Businesses can use Swiss cutting to make parts with standards as small as ±0.0002 inches, which is needed for high-end medical, industrial, and military goods.

3. Knowing how to use things and being able to adapt to them

They are also different because they know a lot about the products. A good person who makes turned parts should be able to work with a lot of different metals, from common steels and aluminum to Inconel, titanium, and medical-grade stainless steel.

What material is used for a part often depends on how it will be used in the end. Titanium, for instance, is a good metal for making airplane parts that need to be light and not rust.

It is very important to use medical-grade stainless steel for devices and surgery tools.

Copper and brass are used to connect electrical devices because they are good at moving electricity.

To keep the surface smooth and accurate, the best makers know how each material reacts to different speeds, feeds, tools, and cooling systems during the turning process.

4. Tough systems for quality control

Quality control isn't just a step in high-tolerance output; it's built into the whole process. Coordinate Measuring Machines (CMM) are some of the high-tech tools that the best companies that make turned parts use for checking and measurement.

-

Comparators that let light in

-

Systems for seeing

-

Micrometers that use light

-

Testers for the finish of the surface

A lot of the time, ISO 9001, AS9100 (for aerospace), or ISO 13485 (for medical) certify quality systems. This shows that they can meet and keep high customer and government standards. Not only does real-time SPC data collection keep the quality of the goods the same, but it also does this.

5. Get technical and modeling help from inside the company

Many of the best makers can do more than just machine parts; they can also help with planning and make samples. A maker might give advice on design for manufacturability (DFM), material choice, and tolerance possibility when they work with a customer during the design process.

Engineers can quickly try and improve ideas before moving on to full-scale production with Swiss machining for in-house prototypes. This way of putting together different parts cuts down on wait times, fixes design issues, and speeds up the process of making a product.

6. Automation and the power to grow

If you hire a world-class turned parts maker, they can make a few high-quality parts and then make a lot of them without lowering the quality. Automation tools like Swiss-type lathes, automatic part handling, and bar feeders allow production to run 24 hours a day, seven days a week without any workers. In this level of automation:

-

Brings down the cost of work

-

It makes more work possible.

-

Makes stability better

-

Cuts down on lead times

As long as the maker can provide the same level of accuracy and trustworthiness, it doesn't matter if the customer wants 10 test parts or 100,000 production pieces.

Different areas have very different needs when it comes to personalization and business understanding. Parts for medical equipment might need to be packed in clean rooms and have finishes that are safe for live things. On the other hand, aerospace parts need to be able to be tracked and approved to meet international standards. A good person who makes turned parts is aware of these small needs and adapts their work to meet them.

Not only that, but they also follow rules and laws, like the FDA and ISO 13485 for medical tools.

The aerospace and defense businesses use AS9100 and NADCAP.

Electronics that follow the rules for RoHS and REACH

Their customers may not have to deal with pricey compliance issues because they can tailor their services to meet their needs.

7. The supply chain's dependability and on-time delivery

Dependability is just as important as accuracy. Most of the time, industries with high flexibility have to meet tight schedules and use just-in-time (JIT) delivery methods. To make sure that parts always come on time, a dependable company that makes turned parts invests in good transportation, inventory management systems, and ERP software.

As the global supply chain becomes less steady, companies that can make items locally, keep stock on hand, and turn things around quickly (thanks to Swiss machining) become very valuable partners for OEMs and Tier 1 providers.

8. Constant funding and new ideas

To stay ahead of the competition, a top-notch maker of made parts spends money on new technologies, training, and growth. To do this, Swiss CNC tools with more than one axis need to be upgraded.

-

Using AI to guess when repairs are needed

-

IoT lets you keep an eye on machines all the time

-

Using business methods that are good for the world

They make better parts faster and for less money by staying on the cutting edge. This also makes sure that their skills will be useful in the future when customer needs change.

That being said

A good machine shop pays close attention to details, can handle many tasks, and is dedicated to quality. A top-tier turned parts maker, on the other hand, is dedicated to these things. Leading makers play a big role in many important areas because they use Swiss machining to make things with tight tolerances and offer technical support, quality assurance, and solutions that can be scaled up or down.

As parts get more complicated and standards get tighter, there will be a greater need for people who can make turned parts. If a business wants to find a producing partner that they can trust and work with for a long time, they should look for these qualities. When making things with a high range, accuracy isn't a nice-to-have; it's a must.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness