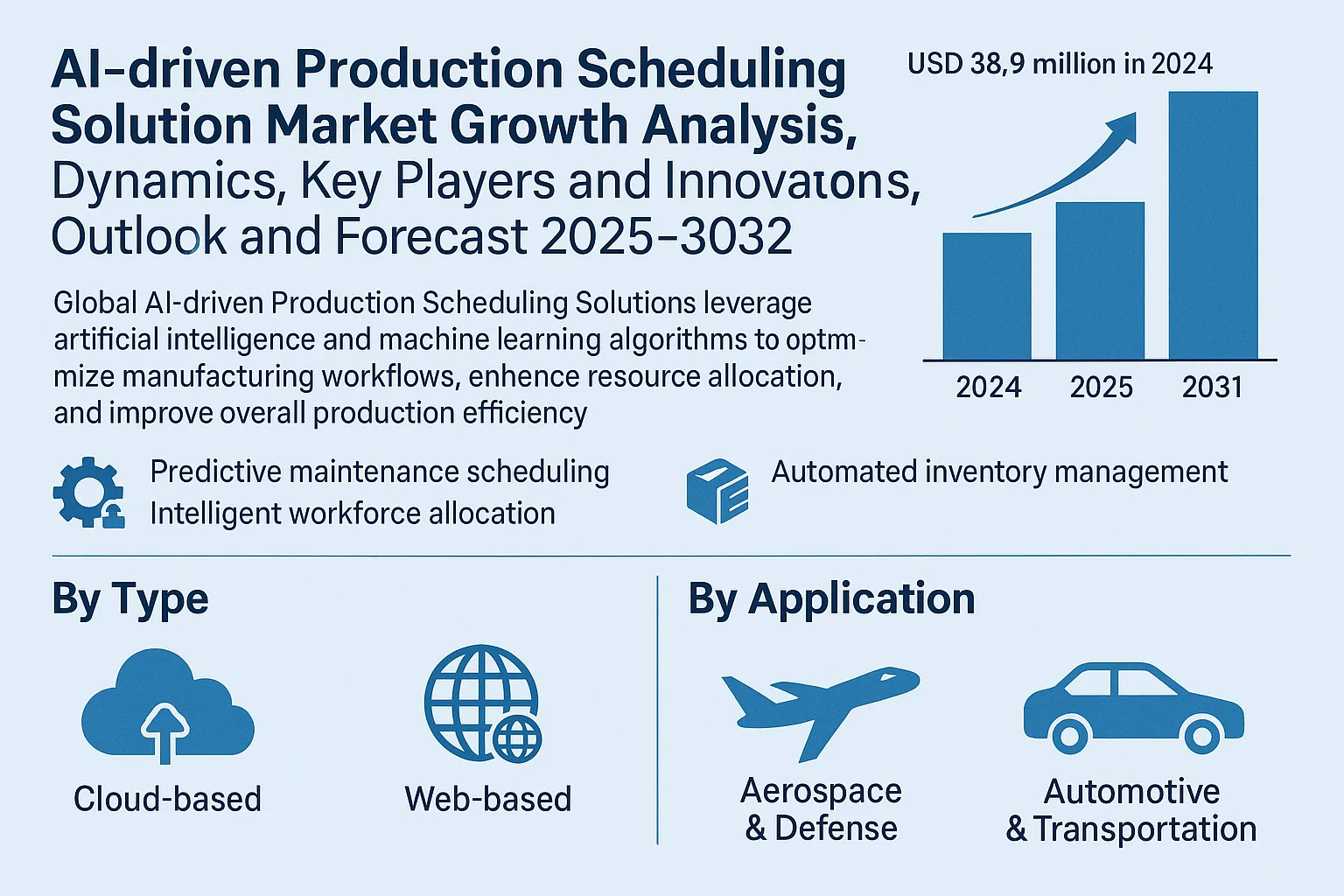

AI-driven Production Scheduling Solution Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2025-2032

MARKET INSIGHTS

Global AI-driven Production Scheduling Solution market size was valued at USD 38.9 million in 2024. The market is projected to grow from USD 43.6 million in 2025 to USD 87.7 million by 2031, exhibiting a CAGR of 12.1% during the forecast period.

AI-driven Production Scheduling Solutions leverage artificial intelligence and machine learning algorithms to optimize manufacturing workflows, enhance resource allocation, and improve overall production efficiency. These advanced systems analyze real-time operational data, predict potential bottlenecks, and dynamically adjust production schedules to maximize throughput while minimizing downtime. The solutions encompass capabilities such as predictive maintenance scheduling, intelligent workforce allocation, and automated inventory management.

The market growth is primarily driven by increasing adoption of Industry 4.0 technologies, growing emphasis on operational efficiency, and rising demand for smart manufacturing solutions. Cloud-based deployment models are gaining particular traction due to their scalability and real-time accessibility, projected to account for over 45% of the market by 2026. Key industry players like o9 Solutions and C3.ai are expanding their AI capabilities through strategic partnerships, while manufacturing giants increasingly integrate these solutions into their digital transformation initiatives to maintain competitive advantage.

MARKET DYNAMICS

MARKET DRIVERS

Increasing Complexity in Manufacturing Operations Accelerates AI Adoption

Modern manufacturing environments face unprecedented complexity due to globalized supply chains, fluctuating demand, and the need for mass customization. Traditional scheduling methods struggle to adapt to real-time disruptions, creating inefficiencies that cost manufacturers billions annually. AI-driven production scheduling solutions dynamically optimize workflows by processing real-time data from IoT devices, ERP systems, and supplier networks. Facilities implementing these solutions report 15-30% improvements in production throughput while reducing inventory costs by up to 25%. The automotive sector leads adoption with 43% of tier-1 suppliers now utilizing predictive scheduling algorithms to manage just-in-time manufacturing.

Industry 4.0 Investments Create Favorable Ecosystem

The global Industry 4.0 market size exceeding $130 billion demonstrates significant infrastructure support for AI scheduling solutions. Smart factories increasingly deploy edge computing architectures that enable real-time AI decision-making at the production line level. Semiconductor manufacturers using these systems achieved 22% shorter cycle times during recent supply chain disruptions. Government initiatives like Germany's Platform Industrie 4.0 and China's Made in China 2025 policy further stimulate adoption through tax incentives and digital transformation grants.

Cloud Computing Democratizes Advanced Scheduling Capabilities

Cloud-based deployment now accounts for 62% of new AI scheduling implementations, eliminating upfront infrastructure costs that previously limited adoption to large enterprises. Mid-market manufacturers gain access to enterprise-grade optimization through subscription models priced 30-40% below on-premise solutions. Recent platform enhancements incorporate digital twin technology, allowing manufacturers to simulate schedule changes before implementation with 95%+ accuracy in outcome prediction.

MARKET RESTRAINTS

Legacy System Integration Challenges Impede Rollout

While AI scheduling promises significant benefits, 58% of manufacturers report integration difficulties with existing MES and ERP systems. Data silos and incompatible protocols create implementation timelines averaging 9-15 months for comprehensive deployments. The aerospace sector faces particular challenges where certification requirements limit software update frequencies, causing lag between AI recommendations and executable schedules.

Additional Constraints

Workforce Resistance to Autonomous Decision-Making

Production managers accustomed to manual scheduling often distrust algorithmic recommendations, especially when redundancies are suggested. Change management accounts for 30% of total implementation costs as organizations retrain staff to interpret AI-driven insights rather than override them.

Regulatory Uncertainty in Critical Industries

Pharmaceutical and defense manufacturers face strict validation requirements for scheduling changes. Recent FDA guidance on continuous manufacturing highlights gaps in current AI solutions' audit trail capabilities, delaying adoption in regulated environments.

MARKET OPPORTUNITIES

Supply Chain Volatility Creates New Optimization Horizons

The post-pandemic emphasis on supply chain resilience drives demand for multi-echelon inventory optimization within scheduling platforms. Solutions incorporating supplier risk analytics command 20-25% premium pricing while reducing stockout risks by 40%. Automotive OEMs now require suppliers to demonstrate AI-driven scheduling capabilities as part of vendor qualification processes.

Sustainability Initiatives Align with Efficiency Gains

Energy-aware scheduling algorithms that minimize carbon footprint during production are gaining traction, particularly in the EU where carbon border taxes take effect. Early adopters report 15-18% reductions in energy consumption through intelligent batch scheduling that optimizes equipment usage during off-peak utility rates.

Edge AI Enables Real-Time Shop Floor Adaptation

Next-generation solutions embed lightweight AI models directly into PLCs and industrial PCs, reducing cloud dependency for time-sensitive decisions. This architecture proves particularly valuable in high-mix environments where changeovers occur every 15-20 minutes. Pilot implementations show 30% faster response to unplanned downtime events compared to cloud-dependent systems.

Segment Analysis:

By Type

Cloud-based Solutions Lead the Market Due to Scalability and Real-time Data Processing Advantages

The market is segmented based on type into:

-

Cloud-based

-

Subtypes: SaaS models, hybrid solutions, and others

-

-

Web-based

-

On-premise

-

Subtypes: Customized enterprise solutions, standalone systems

-

-

Hybrid

-

Others

By Application

Industrial Manufacturing Dominates Application Segment Due to Complex Production Needs

The market is segmented based on application into:

-

Aerospace & Defense

-

Automotive & Transportation

-

Industrial Manufacturing

-

Electronics

-

Others

By Technology

Machine Learning Integration Holds Major Share for Predictive Scheduling Capabilities

The market is segmented based on technology into:

-

Machine Learning

-

Deep Learning

-

Predictive Analytics

-

Natural Language Processing

-

Others

By Deployment Model

Enterprise-wide Deployments Gain Traction for Unified Production Management

The market is segmented based on deployment model into:

-

Departmental

-

Plant-wide

-

Enterprise-wide

-

Supply Chain-wide

COMPETITIVE LANDSCAPE

Key Industry Players

Leading Providers Accelerate AI-Driven Innovation to Capture Market Share

The AI-driven production scheduling solution market features a dynamic competitive environment with both established technology providers and emerging startups. Skyplanner APS and o9 Solutions, Inc. have emerged as frontrunners, collectively commanding significant market share through their comprehensive platforms that integrate machine learning with enterprise resource planning (ERP) systems. The U.S.-based players dominate the landscape, benefiting from early adoption in manufacturing hubs.

Plataine, specializing in IIoT and AI optimization for factories, has gained traction in aerospace and automotive sectors, while C3.ai leverages its enterprise AI expertise to deliver predictive scheduling at scale. These companies have demonstrated 30-45% year-over-year revenue growth since 2022, outperforming market averages.

The market sees intense competition in cloud-based deployments, where Solvoyo and Praxie are disrupting traditional players with SaaS models offering rapid implementation. Meanwhile, European challengers like Cybertec and DUALIS are gaining ground through tailored solutions for medium enterprises.

Strategic moves are shaping the competitive dynamics – from o9 Solutions' 2023 acquisition of process mining firm Fluxicon to Plataine's partnership with Siemens Digital Industries. Such consolidations allow vendors to offer end-to-end digital thread capabilities, a key differentiator as manufacturers seek unified platforms.

List of Key AI-Driven Production Scheduling Solution Providers

-

Skyplanner APS (Denmark)

-

o9 Solutions, Inc. (U.S.)

-

Plataine (Israel)

-

Solvoyo (U.S.)

-

Praxie (U.S.)

-

C3.ai (U.S.)

-

EasyFlow (Germany)

-

SCW.AI (U.K.)

-

GMDH, Inc (U.S.)

-

Cybertec (Germany)

-

DUALIS (Germany)

-

theurer.com GmbH (Germany)

AI-DRIVEN PRODUCTION SCHEDULING SOLUTION MARKET TRENDS

Integration of AI and Predictive Analytics Reshaping Manufacturing Efficiency

The adoption of AI-driven production scheduling solutions is accelerating due to their ability to process vast datasets in real-time, optimize workflows, and reduce operational inefficiencies. These systems leverage machine learning algorithms to predict equipment failures, material shortages, and labor constraints before they disrupt production. Recent advancements in predictive analytics have enabled manufacturers to achieve up to 30% improvement in throughput by dynamically adjusting schedules based on real-time demand and supply fluctuations. Furthermore, AI-powered tools now integrate with IoT-enabled devices, allowing seamless communication between machines and software for end-to-end visibility across production lines.

Other Trends

Cloud-based Deployment Gaining Momentum

Cloud-based AI scheduling solutions are experiencing rapid growth due to their scalability, cost-efficiency, and remote accessibility. Industry data indicates that cloud deployments account for over 45% of new implementations, as they eliminate the need for on-premise infrastructure while enabling real-time collaboration across global teams. This shift has been particularly significant in SMEs, where limited IT resources make cloud adoption a practical choice. The flexibility of web-based and hybrid models further supports multi-site manufacturing operations, ensuring synchronized scheduling even in distributed environments.

Sector-Specific Customization Driving Adoption

Automotive and aerospace manufacturers are leading the adoption of tailored AI scheduling solutions to manage complex assembly processes and stringent compliance requirements. In automotive, just-in-time production models rely on AI to balance supply chain volatility, with some OEMs reporting 20-25% reduction in inventory costs. Meanwhile, industrial manufacturing segments are using these tools to optimize energy-intensive processes, aligning production schedules with off-peak utility rates for additional savings. The ability to customize algorithms for specific operational constraints—such as tooling dependencies in semiconductor fabrication—is proving critical for high-precision industries.

Regional Analysis: AI-driven Production Scheduling Solution Market

North America

North America remains the dominant market for AI-driven production scheduling solutions, fueled by rapid Industry 4.0 adoption and substantial investments in smart manufacturing. The U.S., in particular, accounts for the largest regional market share due to its advanced technological infrastructure and early adoption of AI-powered industrial solutions. Key factors driving growth include the strong presence of automotive and aerospace manufacturers leveraging predictive scheduling tools, alongside increasing investments by tech giants in cloud-based solutions. Challenges persist in legacy system integration, but the growing demand for real-time optimization in high-value manufacturing continues to accelerate market expansion.

Europe

The European market demonstrates robust growth, characterized by stringent operational efficiency standards and a thriving industrial automation sector. Germany leads regional adoption, given its extensive manufacturing base and emphasis on digital transformation initiatives under Industry 4.0 policies. There is particular demand for AI scheduling solutions in automotive and pharmaceutical industries, where compliance with tight production timelines is critical. However, data privacy concerns under GDPR and hesitancy among small-to-midsize manufacturers pose adoption barriers. Several EU-funded smart manufacturing projects are gradually overcoming these challenges by demonstrating ROI in dynamic scheduling applications.

Asia-Pacific

Asia-Pacific is witnessing the fastest market growth, with China, Japan, and South Korea spearheading adoption across electronics and automotive sectors. China's dominance stems from government-backed smart manufacturing initiatives and the presence of massive production facilities requiring complex scheduling. Japan's focus on Lean manufacturing principles synergizes well with AI-driven optimization tools. While India shows promising growth due to expanding automotive and textile industries, uneven digital infrastructure across the region creates adoption disparities. Cloud-based solutions are gaining traction, particularly among multinational manufacturers with distributed supply chains.

South America

The South American market is developing steadily, with Brazil and Argentina showing gradual uptake in automotive and food processing industries. Economic volatility sometimes restricts large-scale investments, prompting manufacturers to prioritize basic scheduling modules over comprehensive AI solutions. However, the growing need to compete in global supply chains is driving interest in production optimization tools. Local providers are emerging with simpler, cost-effective versions of AI scheduling software tailored for mid-sized factories. The region offers long-term potential as manufacturing sectors mature and digital transformation gains momentum.

Middle East & Africa

This region represents an emerging market where adoption is concentrated in oil & gas and discrete manufacturing sectors. UAE and Saudi Arabia lead in implementing advanced scheduling solutions, often integrated with broader smart factory initiatives. While market penetration remains low compared to other regions, increasing foreign direct investment in manufacturing and government digital transformation agendas are creating demand. Infrastructure limitations and skills gaps currently restrain faster adoption, though partnerships between local manufacturers and global AI solution providers are beginning to bridge these gaps through customized implementations.

Report Scope

This market research report offers a holistic overview of global and regional markets for the forecast period 2025–2032. It presents accurate and actionable insights based on a blend of primary and secondary research.

Key Coverage Areas:

-

✅ Market Overview

-

Global and regional market size (historical & forecast)

-

Growth trends and value/volume projections

-

-

✅ Segmentation Analysis

-

By product type or category

-

By application or usage area

-

By end-user industry

-

By distribution channel (if applicable)

-

-

✅ Regional Insights

-

North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

-

Country-level data for key markets

-

-

✅ Competitive Landscape

-

Company profiles and market share analysis

-

Key strategies: M&A, partnerships, expansions

-

Product portfolio and pricing strategies

-

-

✅ Technology & Innovation

-

Emerging technologies and R&D trends

-

Automation, digitalization, sustainability initiatives

-

Impact of AI, IoT, or other disruptors (where applicable)

-

-

✅ Market Dynamics

-

Key drivers supporting market growth

-

Restraints and potential risk factors

-

Supply chain trends and challenges

-

-

✅ Opportunities & Recommendations

-

High-growth segments

-

Investment hotspots

-

Strategic suggestions for stakeholders

-

-

✅ Stakeholder Insights

-

Target audience includes manufacturers, suppliers, distributors, investors, regulators, and policymakers

-

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global AI-driven Production Scheduling Solution Market?

-> The global AI-driven Production Scheduling Solution market was valued at USD 38.9 million in 2024 and is projected to reach USD 87.7 million by 2031.

Which key companies operate in Global AI-driven Production Scheduling Solution Market?

-> Key players include Skyplanner APS, o9 Solutions, Inc., Plataine, Solvoyo, Praxie, C3.ai, EasyFlow, SCW.AI, GMDH, Inc, and Cybertec, among others.

What are the key growth drivers?

-> Key growth drivers include rising demand for manufacturing automation, increasing complexity in supply chains, and the need for real-time production optimization.

Which region dominates the market?

-> North America holds the largest market share, while Asia-Pacific is expected to witness the fastest growth during the forecast period.

What are the emerging trends?

-> Emerging trends include integration with IoT platforms, predictive maintenance capabilities, and cloud-based deployment models.

https://sidintelmarketresearch.blogspot.com/2025/09/spinal-fluid-manometer-market-growth_10.html

https://sidintelmarketresearch.blogspot.com/2025/09/sectional-valve-market-growth-analysis_10.html

https://sidintelmarketresearch.blogspot.com/2025/09/lightning-warning-system-market-growth_10.html

https://sidintelmarketresearch.blogspot.com/2025/09/vehicle-exhaust-emission-control_9.html

https://sidintelmarketresearch.blogspot.com/2025/09/industrial-grade-ferrous-sulfate.html

https://sidintelmarketresearch.blogspot.com/2025/09/roof-lift-system-market-growth-analysis.html

https://sidintelmarketresearch.blogspot.com/2025/09/graphite-braided-packing-market-growth.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness