How Do Turbine Flow Meters Detect Changes in Flow Velocity or Turbulence?

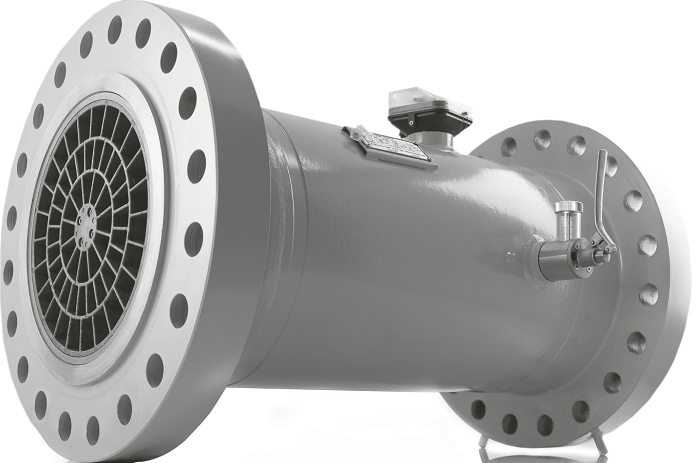

Turbine flow meters are widely used in industries that require precise measurement of liquid and gas flow. Their design is straightforward, but their ability to capture variations in flow velocity and turbulence is the result of careful engineering. These meters operate on the principle that fluid moving through a pipe will rotate a turbine at a rate proportional to its velocity. Sensors record the rotation, which is then translated into flow readings.

To understand how turbine flow meters detect changes in flow velocity or turbulence, it is useful to break the process down into a series of mechanisms. Each stage provides insight into how the meter transforms mechanical motion into meaningful data.

The Fundamental Role of Turbine Flow Meters

Turbine flow meters stand out for their balance of simplicity and accuracy. They are used in water treatment, oil and gas, aerospace, and chemical processing. Their advantage lies in their ability to measure both steady and variable flow conditions. These meters do not only record average flow but also detect subtle changes in turbulence or velocity. This makes them valuable tools for operations where flow quality and consistency are essential.

Step by Step Detection Process

1. Fluid Entry and Initial Flow Conditions

When fluid first enters turbine flow meters, it passes through a flow straightener or conditioning section. This component reduces swirl and prepares the fluid for accurate measurement. At this stage, any existing turbulence or irregularity in the fluid will already begin influencing how the flow is shaped. The flow straightener does not eliminate all turbulence but directs it into a form that the turbine blades can register.

2. Blade Interaction with Flow Velocity

The turbine itself consists of precisely angled blades. As the fluid passes through, its velocity causes the blades to rotate. The speed of rotation is directly proportional to the flow velocity. If turbulence increases, the impact on the blades changes. Variations in pressure and eddies in the flow alter the rotation speed and sometimes cause fluctuations in rotational consistency. These fluctuations provide early indications of turbulence.

3. Conversion of Mechanical Energy into Rotational Speed

The mechanical interaction between the fluid and the blades is simple but highly sensitive. Even small changes in flow velocity result in measurable differences in turbine rotation. For instance, when the flow accelerates, the turbine spins faster. When the flow slows or becomes turbulent, irregularities appear in the rotation pattern. This proportional relationship allows turbine flow meters to detect not only average velocity but also rapid shifts.

4. Magnetic or Optical Sensors Capture Movement

Most turbine flow meters use magnetic or optical sensors to capture blade movement. A magnet embedded in the rotor or blades passes by a pickup coil, generating an electrical pulse. Optical systems use light detection instead. Each pulse represents one rotation or part of a rotation. When turbulence occurs, the spacing between pulses becomes less consistent. The sensors detect this irregularity and send it to the processing unit for analysis.

5. Pulse Frequency Translated into Flow Data

The meter’s electronics translate the frequency of pulses into flow rate. A stable flow produces evenly spaced pulses, while turbulence creates variable intervals. The ability of turbine flow meters to detect turbulence comes from their sensitivity to these small variations. By monitoring not only the average pulse frequency but also irregular patterns, the system identifies changes in flow velocity and turbulence.

6. Turbulence Indicated by Irregular Pulse Patterns

One of the clearest signs of turbulence is irregularity in pulse patterns. While average velocity can still be measured, the variations in pulse spacing indicate unsteady flow. In industries such as aerospace or chemical processing, these irregularities matter. They may suggest pressure drops, pipe restrictions, or pump malfunctions. Turbine flow meters provide real-time visibility into these issues by capturing turbulence at the sensor level.

7. Electronics Smooth Data but Retain Variability

Modern turbine flow meters are equipped with electronic circuits that smooth data for readability. However, they also retain information about variability. This means the operator sees both a clear average flow rate and signals of turbulence. The electronics ensure that sudden surges or drops caused by flow irregularities are not ignored but recorded for diagnostic purposes.

8. Temperature and Viscosity Adjustments

Flow conditions are not shaped by velocity alone. Changes in fluid temperature or viscosity also influence turbulence and blade rotation. Turbine flow meters often include compensation mechanisms for these factors. If the viscosity rises, the turbine may rotate differently even at the same velocity. The meter accounts for this to maintain accuracy, ensuring that turbulence detection remains reliable.

9. Real-Time Monitoring of Flow Instability

Industrial systems rely on turbine flow meters for real-time detection of unstable flows. For example, in an oil pipeline, sudden turbulence may indicate leaks or blockages. The meter detects these changes instantly by capturing irregular turbine rotation. This real-time monitoring capability is one reason turbine flow meters remain popular despite competition from other technologies.

10. Long-Term Data Patterns Reflect Flow Behavior

Beyond immediate detection, turbine flow meters can log data over time. Patterns of turbulence become visible across hours, days, or weeks. Operators can use this information to predict system behavior and schedule maintenance. For example, repeated turbulence at specific times may correspond to pump cycles or process changes. The meter not only detects immediate changes but also contributes to long-term system understanding.

Applications of Turbulence Detection

Oil and Gas Industry

In oil pipelines, turbulence can reduce efficiency and damage equipment. Turbine flow meters provide accurate measurements while signaling abnormal flow conditions. Detecting turbulence early prevents costly breakdowns.

Aerospace Systems

Aircraft fuel systems demand precise flow monitoring. Turbulence in fuel lines can disrupt engine performance. Turbine flow meters track these irregularities with sensitivity, supporting safety and reliability.

Water Treatment Plants

In municipal water systems, flow consistency is vital. Turbulence can lead to uneven distribution or stress on pipes. Turbine flow meters help operators identify and address these issues quickly.

Conclusion

Turbine flow meters detect changes in flow velocity and turbulence through a combination of mechanical and electronic processes. The steps begin with fluid entry, pass through blade interaction, and continue with sensors capturing rotational speed. Irregular pulse patterns reveal turbulence, while electronics refine and present the data. Over time, turbine flow meters provide both real-time detection and long-term analysis of flow conditions. Their balance of simplicity, sensitivity, and reliability makes them essential in industries where flow quality directly affects safety and efficiency. By translating subtle changes in velocity into readable signals, turbine flow meters ensure that turbulence is not hidden but fully understood.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness