Which types of materials can be processed using CNC machining services?

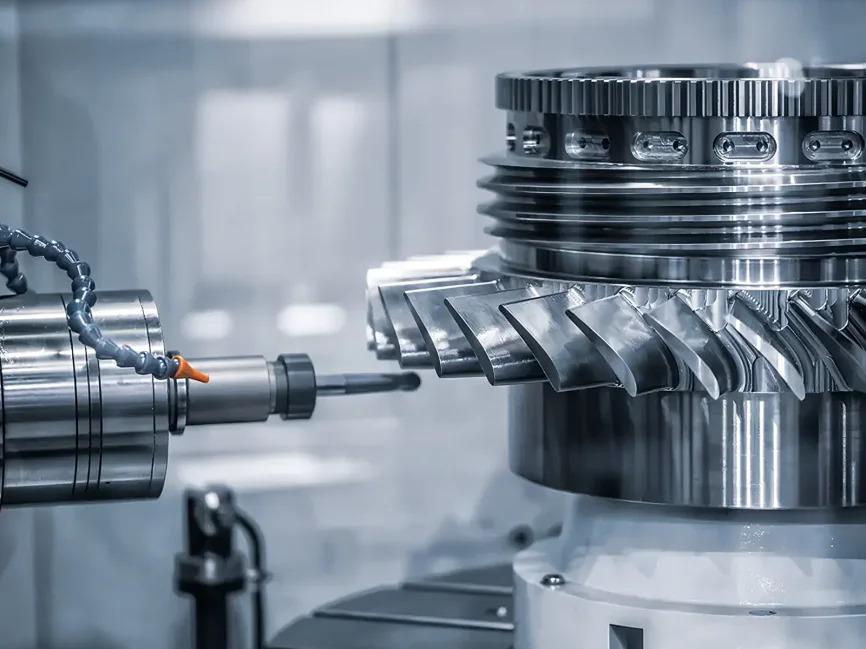

A CNC (Computer Numerical Control) machine is known for its versatility, precision, and ability to handle a wide range of materials. From metals and plastics to composites and even wood, these machines can be programmed to manufacture complex and highly accurate parts out of various materials. The choice of material depends on the application, performance requirements, and budget of the project and is handled efficiently through a CNC machining service.

Below is an overview of the most common types of materials used in CNC machining:

1. Metals

Metals are widely used in CNC machining due to their strength, durability, and performance in mechanical applications. Some of the most frequently machined metals include:

• Aluminum

Lightweight, corrosion-resistant, and easy to machine, aluminum is one of the most popular CNC materials. It’s ideal for aerospace, automotive, and consumer electronics applications.

• Steel

Steel offers excellent strength and toughness. Different grades like carbon steel, alloy steel, and stainless steel are used depending on whether corrosion resistance or hardness is required.

• Brass

Known for its ease of machining and attractive finish, brass is often used for fittings, decorative parts, and electrical components.

• Copper

Highly conductive and corrosion-resistant, copper is used for electrical parts, heat exchangers, and specialty components.

• Titanium

Strong, lightweight, and biocompatible, titanium is commonly used in the aerospace, medical, and defense industries, though it’s more difficult and expensive to machine.

2. Plastics

CNC machining also supports a wide variety of plastics, offering lightweight and cost-effective solutions for many industries.

• ABS (Acrylonitrile Butadiene Styrene)

Strong, impact-resistant, and versatile, ABS is used in prototyping, enclosures, and automotive parts.

• Nylon

Known for its durability and resistance to wear, nylon is used in mechanical components like gears, bushings, and bearings.

• Polycarbonate

This transparent and tough plastic is suitable for lenses, safety equipment, and housings.

• PEEK (Polyetheretherketone)

A high-performance thermoplastic, PEEK is chemical-resistant and heat-resistant, often used in aerospace, medical, and industrial applications.

• Delrin (Acetal)

Delrin is a strong and rigid plastic used in high-precision parts like gears and seals.

3. Composites

Some CNC machining services work with composite materials such as carbon fiber-reinforced plastics or fiberglass. These materials combine light weight with high strength and are commonly used in aerospace, sports equipment, and automotive parts.

4. Wood and Foam

CNC machines, particularly routers, can also process wood, MDF (Medium Density Fiberboard), and rigid foam. These materials are often used in prototyping, furniture production, signage, and mold-making.

Choosing the Right Material

The material you select for CNC machining depends on several factors:

-

Mechanical properties (e.g., strength, weight, hardness)

-

Thermal and chemical resistance

-

Cost and availability

-

Ease of machining

-

Application requirements (e.g., food-grade, medical-grade, outdoor use)

Machining service providers often assist clients in choosing the best material for their specific project based on these criteria.

Conclusion

CNC machining services can work with a broad spectrum of materials, including metals, plastics, composites, and more. This flexibility makes CNC machining a go-to solution across industries such as aerospace, automotive, electronics, medical, and industrial equipment. By selecting the right material for your application, you can achieve the perfect balance of performance, cost, and manufacturability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness