Food Enzymes Market to be growing at a CAGR of 7.64% in the forecast period of 2022 to 2029.

The Food Enzymes Market sector is undergoing rapid transformation, with significant growth and innovations expected by 2029. In-depth market research offers a thorough analysis of market size, share, and emerging trends, providing essential insights into its expansion potential. The report explores market segmentation and definitions, emphasizing key components and growth drivers. Through the use of SWOT and PESTEL analyses, it evaluates the sector’s strengths, weaknesses, opportunities, and threats, while considering political, economic, social, technological, environmental, and legal influences. Expert evaluations of competitor strategies and recent developments shed light on geographical trends and forecast the market’s future direction, creating a solid framework for strategic planning and investment decisions.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-food-enzymes-market

Which are the top companies operating in the Food Enzymes Market?

The report profiles noticeable organizations working in the water purifier showcase and the triumphant methodologies received by them. It likewise reveals insights about the share held by each organization and their contribution to the market's extension. This Global Food Enzymes Market report provides the information of the Top Companies in Food Enzymes Market in the market their business strategy, financial situation etc.

Sunson Industry Group Co., Ltd., Aumenzymes, Associated British Foods plc., ENGRAIN, Kerry Group plc, Brenntag SE Messeallee, Advanced Enzyme Technologies, Amano Enzyme Co. Ltd., Chr. Hansen Holdings A/S, Novozymes, DSM, BASF SE, DuPont, Jiangsu Boli Bioproducts Co., Ltd., Amway Corp., PURATOS, Lumis Biotech Pvt. Ltd., Lonza, Asahi Kasei Pharma Corporation, F. Hoffmann-La Roche Ltd.

Report Scope and Market Segmentation

Which are the driving factors of the Food Enzymes Market?

The driving factors of the Food Enzymes Market are multifaceted and crucial for its growth and development. Technological advancements play a significant role by enhancing product efficiency, reducing costs, and introducing innovative features that cater to evolving consumer demands. Rising consumer interest and demand for keyword-related products and services further fuel market expansion. Favorable economic conditions, including increased disposable incomes, enable higher consumer spending, which benefits the market. Supportive regulatory environments, with policies that provide incentives and subsidies, also encourage growth, while globalization opens new opportunities by expanding market reach and international trade.

Food Enzymes Market - Competitive and Segmentation Analysis:

**Segments**

- **Type Segment**: The type segment of the global food enzymes market is expected to witness significant growth during the forecast period. This can be attributed to the increasing demand for various types of food enzymes such as carbohydrases, proteases, and lipases in the food industry to enhance the quality of processed food products. Carbohydrases, in particular, are anticipated to dominate the market due to their wide range of applications in the food and beverage sector.

- **Application Segment**: The application segment of the market is projected to show substantial growth by 2029. Food enzymes find extensive usage in various applications such as bakery, dairy, beverages, confectionery, and processed foods. The rising consumer preference for natural and clean label ingredients in food products is driving the demand for food enzymes in the bakery and dairy sectors.

- **Source Segment**: Within the source segment, microorganisms are expected to hold a significant share in the global food enzymes market during the forecast period. Microbial food enzymes are widely used in the food industry for their effectiveness in improving processing efficiency and product quality. Moreover, the ease of production and scalability of microbial enzymes make them a preferred choice among food manufacturers.

**Market Players**

- **Novozymes A/S**: Novozymes A/S is a key player in the global food enzymes market, offering a wide range of enzyme solutions for various food applications. The company focuses on research and development to innovate new enzyme products that cater to the evolving needs of the food industry.

- **DuPont**: DuPont is another prominent player in the market, known for its diverse portfolio of food enzymes for applications in bakery, dairy, and beverages. The company emphasizes sustainability and bioinnovation in its enzyme solutions to address consumer demands for clean label and eco-friendly ingredients.

- **DSM**: DSM is a leading supplier of food enzymes globally, providing enzymes that enhance the texture, taste, and nutritional value of food products. The company invests heavily in research and development toNovozymes A/S is a significant player in the global food enzymes market and is renowned for its extensive range of enzyme solutions catering to various food applications. The company's strong focus on research and development has positioned it as an innovator in the industry, continuously introducing new enzyme products to meet the evolving needs of the food sector. Novozymes A/S has carved a niche for itself by enhancing the quality and functionality of processed food products through its advanced enzyme technologies. With the increasing demand for natural ingredients and clean label products, the company is well-positioned to capitalize on these trends and maintain its competitive edge in the market.

DuPont, another key player in the food enzymes market, boasts a diverse portfolio of enzyme solutions tailored for applications in bakery, dairy, and beverages. The company is known for its commitment to sustainability and bioinnovation, aligning its enzyme offerings with the growing consumer preference for clean label and eco-friendly ingredients. DuPont's emphasis on environmental responsibility and product innovation has resonated well with consumers and strengthened its position in the market. By leveraging its expertise in enzyme technology and sustainable practices, DuPont is set to drive further growth and expansion in the global food enzymes market.

DSM stands out as a leading supplier of food enzymes worldwide, providing solutions that enhance the texture, taste, and nutritional value of food products. The company's substantial investments in research and development reflect its commitment to innovation and product excellence. DSM's focus on developing enzymes that address key consumer preferences and industry trends underscores its strategic approach to market leadership. By continuously refining its enzyme offerings and staying abreast of market dynamics, DSM remains a trusted partner for food manufacturers seeking high-quality enzyme solutions.

In conclusion, the global food enzymes market is witnessing significant growth driven by the increasing demand for enzyme solutions in various food applications. Companies like Novozymes A/S, DuPont, and DSM play pivotal roles in shaping the market landscape through their innovative products, sustainable practices, and customer-centric approaches. As the market continues to**Market Players:**

- Sunson Industry Group Co., Ltd.

- Aumenzymes

- Associated British Foods plc.

- ENGRAIN

- Kerry Group plc

- Brenntag SE Messeallee

- Advanced Enzyme Technologies

- Amano Enzyme Co. Ltd.

- Chr. Hansen Holdings A/S

- Novozymes

- DSM

- BASF SE

- DuPont

- Jiangsu Boli Bioproducts Co., Ltd.

- Amway Corp.

- PURATOS

- Lumis Biotech Pvt. Ltd.

- Lonza

- Asahi Kasei Pharma Corporation

- F. Hoffmann-La Roche Ltd.

**Market Analysis:**

The global food enzymes market is a dynamic and rapidly expanding sector that is driven by a multitude of factors such as changing consumer preferences, technological advancements, and regulatory developments. As the food industry continues to evolve, food enzymes have become indispensable in improving product quality, enhancing nutritional profiles, and optimizing production processes. The market players mentioned above are at the forefront of innovation, continually developing new enzyme solutions to meet the evolving needs of food manufacturers and consumers alike.

One of the key trends shaping the food enzymes market is the increasing demand for clean label and natural ingredients. Consumers are becoming more conscious about the food they consume, leading to a shift towards products that are free from artificial additives and preservatives. This trend has propelled the use of food enzymes as they help enhance the sensory attributes

Explore Further Details about This Research Food Enzymes Market Report https://www.databridgemarketresearch.com/reports/global-food-enzymes-market

Key Benefits for Industry Participants and Stakeholders: –

- Industry drivers, trends, restraints, and opportunities are covered in the study.

- Neutral perspective on the Food Enzymes Market scenario

- Recent industry growth and new developments

- Competitive landscape and strategies of key companies

- The Historical, current, and estimated Food Enzymes Market size in terms of value and size

- In-depth, comprehensive analysis and forecasting of the Food Enzymes Market

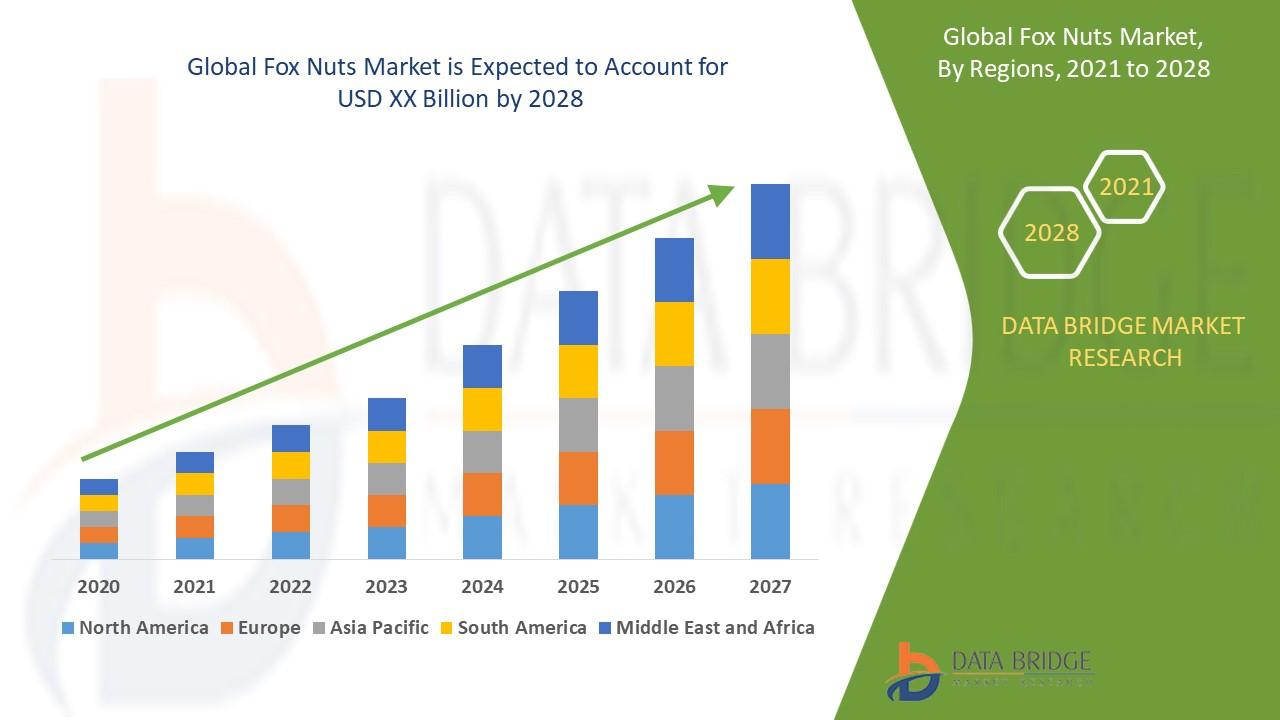

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2029) of the following regions are covered in Chapters

The countries covered in the Food Enzymes Market report are U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of the Middle East and Africa.

Key Questions Answered:

1. What is the Food Enzymes Market?

2. How big is the Food Enzymes Market?

3. What is the growth rate of the Food Enzymes Market?

4. What are the key drivers of the Food Enzymes Market?

5. Which region dominates the Food Enzymes Market?

6. Who are the major players in the Food Enzymes Market?

7. What segments are included in the Food Enzymes Market?

8. What are the challenges facing the Food Enzymes Market?

9. What is the future outlook for the Food Enzymes Market?

10. How can companies benefit from the Food Enzymes Market?

Browse More Reports:

Log Management Market – Industry Trends and Forecast

Wound Dressings Market – Industry Trends and Forecast

Paints and Coatings Market – Industry Trends and Forecast

ECG Cable and ECG Lead Wires Market – Industry Trends and Forecast

Spinal Implants and Surgical Devices Market - Industry Trends and Forecast

Innovation Management Market – Industry Trends and Forecast

Spear Phishing Market – Industry Trends and Forecast

Wearable Medical Devices Market – Industry Trends and Forecast

Sterilization Equipment Market – Industry Trends and Forecast

Data Fabric Market – Industry Trends and Forecast

Cloud Operations Support Systems (OSS) Business Support System (BSS) Market – Industry Trends and Forecast

Internet of Things (IoT) Operating Systems Market – Industry Trends and Forecast

Trade Management Market – Industry Trends and Forecast

Telecom Managed Services Market – Industry Trends and Forecast

Oil Field Communications Market - Industry Trends and Forecast

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 978

Email:- [email protected]