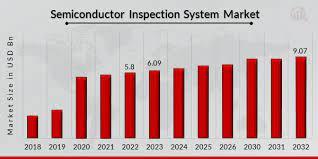

Semiconductor Inspection System Market

Introduction:

Semiconductor Inspection System Market Size is expected to grow USD 9.07 Billion by 2032, at (CAGR) of 5.10% during the forecast period (2023 - 2032).

Semiconductor manufacturing processes demand precision and reliability to ensure the production of high-quality chips used in various electronic devices. The semiconductor inspection system market plays a critical role in this ecosystem by providing advanced tools and technologies for inspecting, detecting defects, and ensuring the quality of semiconductor wafers and chips. This article delves into the dynamics of the semiconductor inspection system market, highlighting key trends, drivers, challenges, and future prospects.

Understanding Semiconductor Inspection Systems:

· Semiconductor inspection systems are specialized equipment used to inspect and analyze semiconductor wafers and chips at different stages of the manufacturing process. These systems employ advanced imaging, metrology, and defect detection techniques to identify defects, anomalies, and irregularities that may affect the performance and reliability of semiconductor devices.

Key Market Drivers:

· Demand for High-Quality Semiconductor Devices: With the increasing complexity and miniaturization of semiconductor devices, there is a growing demand for inspection systems capable of detecting defects at the nanometer scale. Semiconductor manufacturers require advanced inspection tools to ensure the quality and reliability of their products, particularly in critical applications such as automotive, aerospace, and medical devices.

· Rapid Technological Advancements: Continuous innovations in semiconductor manufacturing processes, materials, and device architectures drive the need for more sophisticated inspection solutions. The development of advanced imaging techniques, such as optical inspection, electron microscopy, and X-ray imaging, enables semiconductor manufacturers to achieve higher levels of accuracy and sensitivity in defect detection.

· Stringent Quality Standards and Regulations: The semiconductor industry is subject to stringent quality standards and regulations, necessitating the implementation of robust inspection and quality control measures. Compliance with international standards and customer specifications requires semiconductor manufacturers to invest in state-of-the-art inspection systems capable of meeting industry requirements and ensuring product reliability.

Get a free sample @ https://www.marketresearchfuture.com/sample_request/1797

Key Companies in the Semiconductor Inspection System market include:

· Rudolph Technologies, Inc.

· JEOL Ltd.

· Hitachi High-Technologies Corp

· Nanometrics, Inc.

· KLA-Tencor Corporation

· Applied Materials, Inc.

· Nikon Metrology NV

· Lasertec Corporation

· Thermo Fisher Scientific, Inc.

· ASML Holding NV.

Challenges and Opportunities:

· Complexity of Semiconductor Devices: As semiconductor devices become more complex and integrated, the challenges associated with defect detection and characterization increase. Semiconductor inspection systems must keep pace with evolving technologies and address the unique requirements of advanced device architectures, such as FinFETs, 3D NAND, and advanced packaging techniques.

· Cost and Scalability: The high cost of semiconductor inspection equipment poses a significant challenge for semiconductor manufacturers, especially for small and medium-sized enterprises (SMEs). Balancing the cost-effectiveness and scalability of inspection solutions while maintaining high-quality standards remains a key consideration for industry stakeholders.

· Integration with Smart Manufacturing: The emergence of smart manufacturing and Industry 4.0 concepts presents opportunities for integrating semiconductor inspection systems into automated production environments. Real-time data analytics, predictive maintenance, and machine learning algorithms can enhance the efficiency and effectiveness of semiconductor inspection processes, enabling proactive defect prevention and optimization of manufacturing workflows.

Future Outlook:

The semiconductor inspection system market is poised for growth driven by ongoing technological advancements, increasing semiconductor complexity, and the proliferation of applications requiring high-performance chips. As semiconductor manufacturers continue to invest in process optimization and quality assurance, the demand for advanced inspection solutions will remain strong, driving innovation and market expansion in the years to come. Collaborative efforts among industry players, research institutions, and regulatory bodies will play a crucial role in shaping the future of semiconductor inspection technologies and ensuring the continued success of the semiconductor industry.

Get a regional report on Japan Semiconductor Inspection System Market

Get a regional report on German Semiconductor Inspection System Market

Get a regional report on French Semiconductor Inspection System Market