Introduction:

Industrial Metrology Market Size is expected to grow USD 18.5 Billion by 2032, at (CAGR) of 6.50% during the forecast period (2023 - 2032).

In the realm of manufacturing, precision is paramount. From ensuring components fit together seamlessly to maintaining strict quality standards, precision plays a crucial role in the success of industrial operations. This is where industrial metrology comes into play. Industrial metrology involves the measurement and inspection of various components and products to ensure they meet exacting standards and specifications. As manufacturing processes become increasingly complex and demands for quality continue to rise, the industrial metrology market is experiencing steady growth and evolution.

Driving Forces Behind the Growth:

Several factors are driving the growth of the industrial metrology market:

· Quality Assurance Requirements: In industries such as automotive, aerospace, and healthcare, where safety and reliability are paramount, there is a growing need for precise measurement and inspection techniques to ensure product quality and compliance with regulatory standards.

· Advancements in Manufacturing Technologies: The advent of Industry 4.0 technologies, such as automation, robotics, and additive manufacturing, has led to more complex and interconnected manufacturing processes. Industrial metrology solutions play a critical role in optimizing these processes by providing accurate measurement data for process control and optimization.

· Demand for High-precision Components: With the increasing miniaturization of components and the demand for higher precision in products such as electronics, medical devices, and semiconductors, there is a corresponding need for metrology solutions capable of measuring at the micron and even nanometer scale.

· Globalization of Manufacturing: As manufacturing becomes more globalized, companies are facing pressure to maintain consistent quality standards across geographically dispersed operations. Industrial metrology solutions enable companies to standardize measurement and inspection processes across locations, ensuring uniform quality regardless of geographical location.

Key Technologies Driving Innovation:

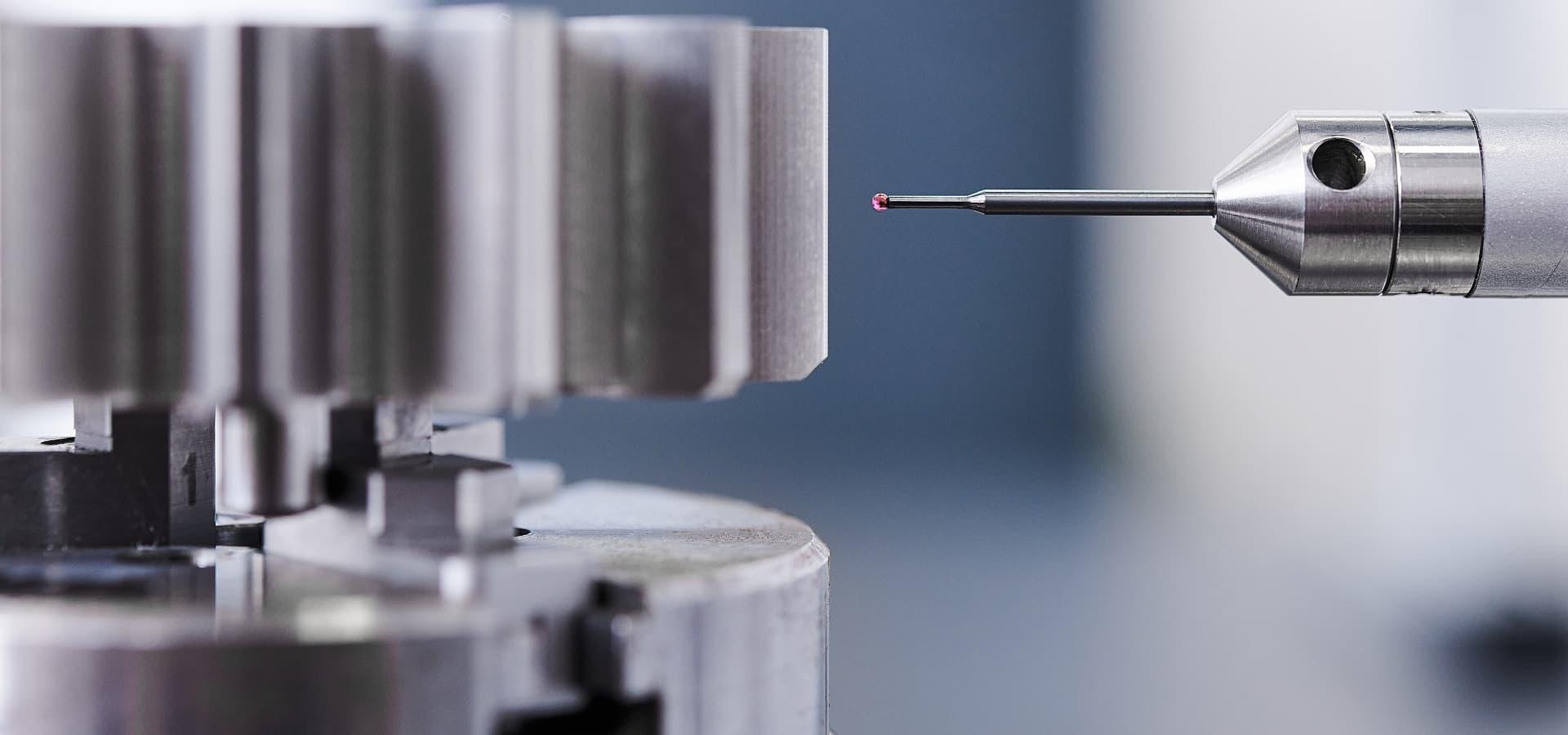

The industrial metrology market encompasses a wide range of technologies and solutions, including coordinate measuring machines (CMMs), optical and laser-based measurement systems, 3D scanners, and portable metrology devices. Some key technologies driving innovation in the market include:

· 3D Scanning and Imaging: 3D scanning technology allows for the rapid and accurate capture of three-dimensional data, enabling precise measurement and inspection of complex geometries. This technology is particularly valuable in industries such as automotive, aerospace, and consumer electronics for reverse engineering, quality control, and dimensional analysis.

· Non-contact Measurement Techniques: Optical and laser-based measurement systems offer non-contact measurement solutions that are ideal for fragile or sensitive components and surfaces. These systems provide high-speed, high-accuracy measurement capabilities, making them well-suited for applications such as surface roughness measurement, form inspection, and defect detection.

· Portable Metrology Solutions: With the increasing need for flexibility and mobility in manufacturing environments, portable metrology solutions are gaining popularity. These handheld devices enable on-the-spot measurement and inspection, allowing manufacturers to perform quality assurance tasks directly on the shop floor without the need for dedicated measurement labs.

Get a free sample @ https://www.marketresearchfuture.com/sample_request/11813

Key Companies in the Industrial Metrology market include:

· Hexagon AB

· Renishaw PLC

· FARO Technologies

· Nikon Metrology

· Carl Zeiss AG

· Jenoptik AG

· Perceptron

· Automated Precision Inc.

· KLA Corporation

· Applied Materials Inc.

Market Outlook and Opportunities:

The industrial metrology market is poised for continued growth, driven by the increasing adoption of advanced manufacturing technologies, the growing demand for high-precision components, and the emphasis on quality assurance across industries. Key opportunities in the market include:

· Integration with Industry 4.0 Technologies: As manufacturing processes become more digitized and interconnected, there is a growing demand for metrology solutions that seamlessly integrate with other Industry 4.0 technologies such as IoT, artificial intelligence, and cloud computing. Integrated metrology solutions enable real-time data analysis, predictive maintenance, and process optimization, enhancing overall efficiency and productivity.

· Expansion into Emerging Markets: Emerging economies, particularly in Asia-Pacific and Latin America, are witnessing rapid industrialization and growth in manufacturing sectors. This presents significant opportunities for metrology solution providers to tap into new markets and address the evolving needs of manufacturers in these regions.

· Focus on Software and Data Analytics: In addition to hardware solutions, there is a growing emphasis on software and data analytics capabilities in the industrial metrology market. Advanced metrology software offers features such as CAD/CAM integration, statistical analysis, and automated reporting, enhancing the usability and value proposition of metrology solutions for manufacturers.