Introduction:

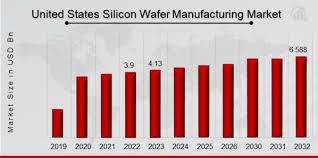

United States Silicon Wafer Manufacturing Market Size is expected to grow USD 6.588 Billion by 2032, at (CAGR) of 6.00% during the forecast period (2024 - 2032).

In the heart of the semiconductor industry lies a critical component: silicon wafers. These thin, circular substrates serve as the foundation for the fabrication of integrated circuits (ICs) and electronic devices. The United States Silicon Wafer Manufacturing Market stands as a cornerstone in the global semiconductor supply chain, driving innovation and powering technological advancements across various sectors. This article delves into the dynamics, trends, and key factors shaping the landscape of silicon wafer manufacturing in the US.

Understanding Silicon Wafer Manufacturing:

Silicon wafers are produced through a highly intricate process known as silicon wafer fabrication. This process involves growing a single crystal ingot of silicon through the Czochralski method or casting molten silicon into a cylindrical shape through the Float-Zone method. The ingot is then sliced into thin, circular wafers using precision sawing techniques. These wafers undergo various manufacturing steps, including polishing, cleaning, doping, and photolithography, to create semiconductor devices such as microchips, memory modules, and sensors.

Market Dynamics:

· Technological Advancements: The US Silicon Wafer Manufacturing Market is driven by continuous technological advancements aimed at improving wafer quality, size, and production efficiency. Advancements in crystal growth techniques, wafer polishing technologies, and defect reduction strategies enable manufacturers to produce high-performance silicon wafers meeting the stringent requirements of advanced semiconductor devices.

· Demand from Electronics and Semiconductor Industries: The robust demand for electronic devices, including smartphones, tablets, laptops, and IoT devices, fuels the growth of the silicon wafer manufacturing market. Moreover, the increasing adoption of emerging technologies such as 5G, artificial intelligence (AI), and automotive electronics drives the demand for advanced semiconductor devices, driving the need for high-quality silicon wafers.

· Rise of Electric Vehicles (EVs) and Renewable Energy: The transition towards electric vehicles and the growing emphasis on renewable energy sources such as solar and wind power drive the demand for power semiconductor devices and photovoltaic (PV) cells. Silicon wafers serve as key components in power semiconductors and solar cells, positioning wafer manufacturers to capitalize on the growth opportunities in these sectors.

· Supply Chain Resilience and Localization: The disruptions caused by the COVID-19 pandemic highlighted the importance of supply chain resilience and localization. As a result, there is a growing trend towards reshoring semiconductor manufacturing and strengthening domestic supply chains in the US. Silicon wafer manufacturers play a critical role in ensuring a reliable and secure supply of semiconductor materials, contributing to the resilience of the semiconductor ecosystem.

· Investments in Research and Development: Continued investments in research and development (R&D) drive innovation in silicon wafer manufacturing, leading to the development of new materials, processes, and technologies. Collaborations between academia, industry, and government institutions foster technological breakthroughs and propel the US Silicon Wafer Manufacturing Market forward.

Market Trends:

· Transition to Larger Wafer Sizes: The semiconductor industry is witnessing a transition towards larger wafer sizes, such as 300mm and beyond, to improve manufacturing efficiency and reduce production costs per die. Silicon wafer manufacturers are investing in equipment and infrastructure upgrades to support the adoption of larger wafer sizes and meet the growing demand for advanced semiconductor devices.

· Focus on Specialty Wafers: With the increasing complexity of semiconductor devices and the emergence of new applications, there is a growing demand for specialty wafers tailored to specific requirements. Specialty wafers, including epitaxial wafers, SOI (Silicon-On-Insulator) wafers, and SiC (Silicon Carbide) wafers, address the needs of niche markets such as power electronics, RF (Radio Frequency) devices, and MEMS (Micro-Electro-Mechanical Systems).

· Integration of Advanced Materials: Silicon wafer manufacturers are exploring the integration of advanced materials such as compound semiconductors, gallium nitride (GaN), and silicon germanium (SiGe) into silicon substrates to enhance device performance and functionality. Hybrid integration techniques enable the development of heterogeneous devices with superior electrical, optical, and thermal properties.

· Sustainability and Environmental Responsibility: Environmental sustainability is becoming increasingly important in silicon wafer manufacturing. Manufacturers are implementing eco-friendly practices, optimizing resource utilization, and reducing waste generation throughout the wafer production process. Moreover, the adoption of renewable energy sources and green manufacturing technologies contributes to the industry's sustainability goals.

Get a free sample @ https://www.marketresearchfuture.com/sample_request/20726

Key Companies in the US silicon wafer manufacturing market include:

· Okmetic Oy

· GlobalWafers Singapore Pte. Ltd

· Sumco Corporation

· Shin-Etsu Chemical Co., Ltd

· Silicon Materials, Inc

· Tokuyama Corporation

· Siltronic AG

· SK Siltron Co., Ltd.

· Shanghai Simgui Technology Co. Ltd.

· Virginia Semiconductor, Inc.

· Wafer Works Corporation

Future Outlook

The US Silicon Wafer Manufacturing Market is poised for continued growth and innovation, driven by the proliferation of electronic devices, advancements in semiconductor technology, and the transition towards advanced manufacturing processes. As the semiconductor industry evolves to meet the demands of emerging applications such as AI, IoT, EVs, and renewable energy, silicon wafer manufacturers will play a central role in enabling technological progress and driving economic prosperity in the United States and beyond.