UPVC Ball Valve for Industrial Use – Trusted by Engineers

In the world of industrial piping and fluid control systems, reliability, durability, and ease of operation are non-negotiable. One component that checks all these boxes—and more—is the UPVC ball valve. Known for its resistance to corrosion, long service life, and cost-effectiveness, this valve has earned a strong reputation among plant engineers, process designers, and maintenance teams across diverse sectors.

In this article, we’ll explore why the UPVC ball valve is a preferred choice for industrial use, what makes it trusted by engineers, and how it can benefit your fluid handling systems.

What is a UPVC Ball Valve?

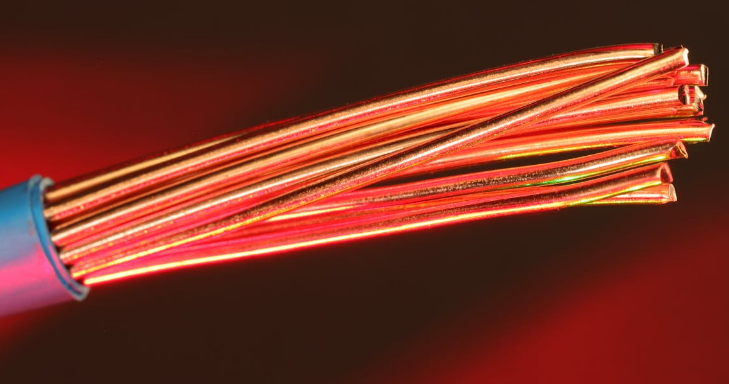

A UPVC (Unplasticized Polyvinyl Chloride) ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of liquid or gas through a pipeline. The ball's rotation, typically by 90 degrees, opens or closes the valve, providing a fast and effective flow control mechanism.

Unlike metal valves, UPVC ball valves are made of high-grade plastic materials, offering excellent resistance to chemicals and environmental factors.

Key Advantages of UPVC Ball Valves in Industrial Applications

- Chemical Resistance

UPVC is inherently resistant to a wide range of chemicals, acids, and alkalis. This makes UPVC ball valves ideal for industries such as:

- Chemical processing

- Water treatment

- Pharmaceuticals

- Agriculture and irrigation

Engineers favor these valves because they remain unaffected by corrosive media, ensuring long-term performance even in aggressive fluid environments.

- Cost-Effective Solution

UPVC valves are significantly more affordable than metal counterparts. They provide a cost-effective solution without compromising performance, especially for low-pressure and non-flammable applications. This is a major factor for engineers working with limited budgets or in large-scale projects.

- Lightweight and Easy to Install

Unlike heavy metal valves, UPVC ball valves are lightweight, reducing the need for additional structural support. This simplifies the installation process, saves labor costs, and minimizes the risk of injury during handling.

The compact design and user-friendly lever mechanism also ensure easy integration into existing systems.

- Corrosion and Weather Resistance

UPVC does not rust, scale, or degrade easily, even when exposed to outdoor environments or moisture. Engineers working on water supply lines, irrigation systems, and outdoor fluid systems prefer UPVC ball valves for their weatherproof properties.

- Low Maintenance Requirements

Once installed, UPVC ball valves require minimal maintenance. The smooth internal surfaces prevent buildup of debris, ensuring consistent flow and reducing the frequency of servicing.

This low-maintenance characteristic is another reason engineers trust UPVC ball valves for both new installations and replacement jobs.

Technical Features of UPVC Ball Valves

- Working Pressure: Typically up to 10 bar (145 psi)

- Temperature Range: 0°C to 60°C (32°F to 140°F)

- End Connections: Threaded (BSP/NPT), solvent socket, flanged

- Operation: Manual lever or actuation-ready designs

- Seals: EPDM or FKM (Viton) for enhanced chemical compatibility

- Sizes Available: From 15mm (½”) up to 110mm (4”) or more, depending on application

These valves are often offered in both single and double union types, allowing for easy removal and maintenance without dismantling the entire pipeline.

Applications of UPVC Ball Valves Across Industries

- Water Treatment Plants

UPVC ball valves are used for controlling water flow in purification, filtration, and storage systems. Their corrosion resistance makes them ideal for handling chlorinated and untreated water.

- Chemical Manufacturing

Engineers in chemical plants use UPVC ball valves to control the movement of aggressive chemicals like acids and alkalis, without the risk of corrosion or contamination.

- Agriculture and Irrigation

Their lightweight construction and ease of use make UPVC valves perfect for field irrigation systems, greenhouses, and hydroponic setups.

- HVAC Systems

UPVC ball valves are used to regulate flow in heating and cooling systems, especially in systems using non-flammable and chemically neutral fluids.

- Food and Beverage Industry

Where metal valves may corrode or react with cleaning agents, UPVC offers a safe and reliable alternative—especially when used with food-grade seal materials.

Why Engineers Trust UPVC Ball Valves?

For engineers and system designers, the primary concerns are reliability, safety, compliance, and performance. UPVC ball valves address all these needs by offering:

- Proven resistance to corrosion and scaling

- Compatibility with a wide range of fluids

- Compliance with international standards for industrial fluid systems

- Low operational torque and quick shut-off capabilities

- Long lifecycle with minimal maintenance

Choosing the Right UPVC Ball Valve Supplier

The quality of a UPVC valve significantly depends on the manufacturer. When selecting a supplier, engineers look for:

- ISO-certified manufacturing processes

- Technical support and material datasheets

- Product traceability and performance testing

- Customization options for size, connection type, and sealing materials

Petron Thermoplast stands out as a trusted UPVC ball valve manufacturer and supplier, offering a wide range of sizes and configurations tailored to industry needs. With a reputation for quality and customer service, Petron Thermoplast is the go-to partner for engineers seeking precision flow control components.

Conclusion

When it comes to industrial flow control, UPVC ball valves have proven their reliability time and again. Their excellent resistance to chemicals, cost-effectiveness, ease of installation, and long service life make them an essential component in countless industrial applications. Engineers trust UPVC ball valves not just for their functional benefits but also for their ability to provide safe, efficient, and trouble-free operation in diverse environments.