ATO Stepper Motors stand out in the industrial automation landscape due to their precise positional control, reliability, and compatibility with a variety of voltage and torque requirements. These motors operate based on open-loop control, eliminating the need for feedback systems, which simplifies integration and reduces cost. Whether it's a NEMA 17 used in compact actuators or a robust NEMA 34 powering conveyor belt systems, ATO Automation offers a range of stepper motors tailored for both light-duty and heavy-duty applications. Their high torque and consistent step angles make them ideal for tasks requiring accurate incremental motion, such as pick-and-place arms, labeling machines, and inspection systems.

Linear stepper motors, another key product in ATO Automation's lineup, offer direct linear motion without the need for additional mechanical transmission elements, reducing wear and increasing efficiency. These are particularly useful in applications such as CNC machining or semiconductor wafer positioning, where micrometer-level accuracy is critical. Likewise, ATO 2-phase stepper motors strike an optimal balance between simplicity and performance, delivering smooth motion with minimal resonance in automated assembly lines.

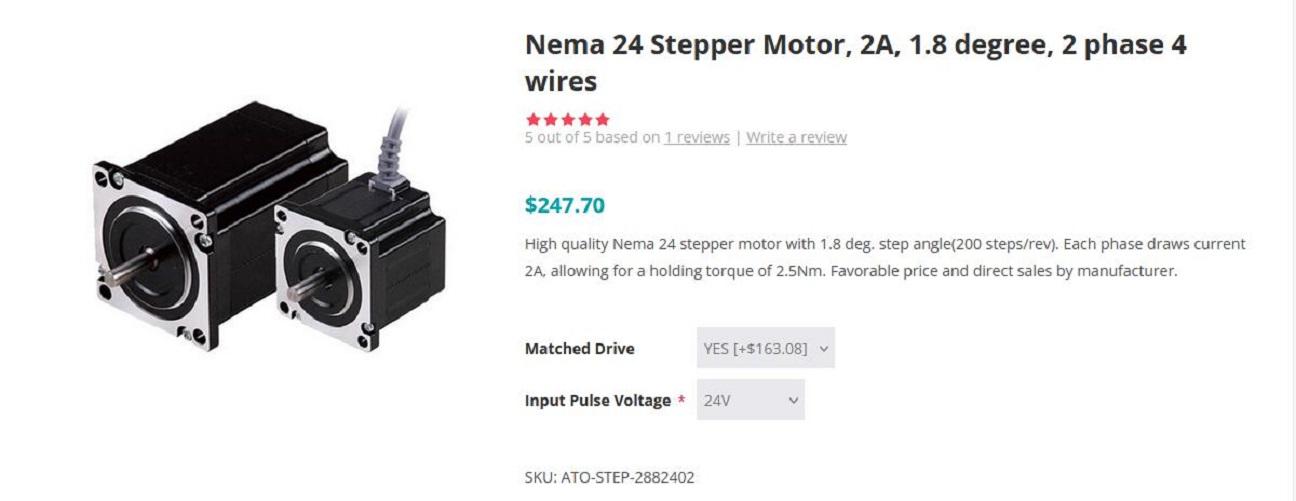

From a voltage perspective, the availability of 5V, 12V, and 24V micro stepper motors ensures integration flexibility across different power architectures. For instance, a 5V stepper motor is excellent for embedded systems and battery-powered devices, whereas a 24V version suits high-torque industrial environments with extended duty cycles. The modular design of these motors allows easy attachment of encoders, gearboxes, and drives, making them adaptable to diverse motion control platforms.

Whether used in robotic welding, automated metering systems, or advanced laboratory instrumentation, ATO Stepper Motors consistently deliver on the promise of accuracy, repeatability, and rugged design. Their ability to retain position without drift, even when de-energized, adds an extra layer of reliability in applications where stability is non-negotiable. These features not only enhance production quality but also reduce downtime, energy consumption, and maintenance needs, making ATO stepper motors a valuable asset across multiple industries.

Linear stepper motors, another key product in ATO Automation's lineup, offer direct linear motion without the need for additional mechanical transmission elements, reducing wear and increasing efficiency. These are particularly useful in applications such as CNC machining or semiconductor wafer positioning, where micrometer-level accuracy is critical. Likewise, ATO 2-phase stepper motors strike an optimal balance between simplicity and performance, delivering smooth motion with minimal resonance in automated assembly lines.

From a voltage perspective, the availability of 5V, 12V, and 24V micro stepper motors ensures integration flexibility across different power architectures. For instance, a 5V stepper motor is excellent for embedded systems and battery-powered devices, whereas a 24V version suits high-torque industrial environments with extended duty cycles. The modular design of these motors allows easy attachment of encoders, gearboxes, and drives, making them adaptable to diverse motion control platforms.

Whether used in robotic welding, automated metering systems, or advanced laboratory instrumentation, ATO Stepper Motors consistently deliver on the promise of accuracy, repeatability, and rugged design. Their ability to retain position without drift, even when de-energized, adds an extra layer of reliability in applications where stability is non-negotiable. These features not only enhance production quality but also reduce downtime, energy consumption, and maintenance needs, making ATO stepper motors a valuable asset across multiple industries.

-

2 Entradas

-

2 Fotos

-

0 Videos

-

Engineer at ATO Stepper Motors Online Shop

-

Vive en New York

-

De New York

-

Female

-

10/01/1999

-

seguida por 0 people

© 2025 flexartsocial.com

Spanish

Spanish

Actualizaciones Recientes

-

0 Commentarios 0 Acciones 419 Views 0 Vista previaPlease log in to like, share and comment!

-

0 Commentarios 0 Acciones 437 Views 0 Vista previa

Quizás te interese…