Inside the Barrelhouse: How Warehouse Location Affects Bourbon and Rye Flavour

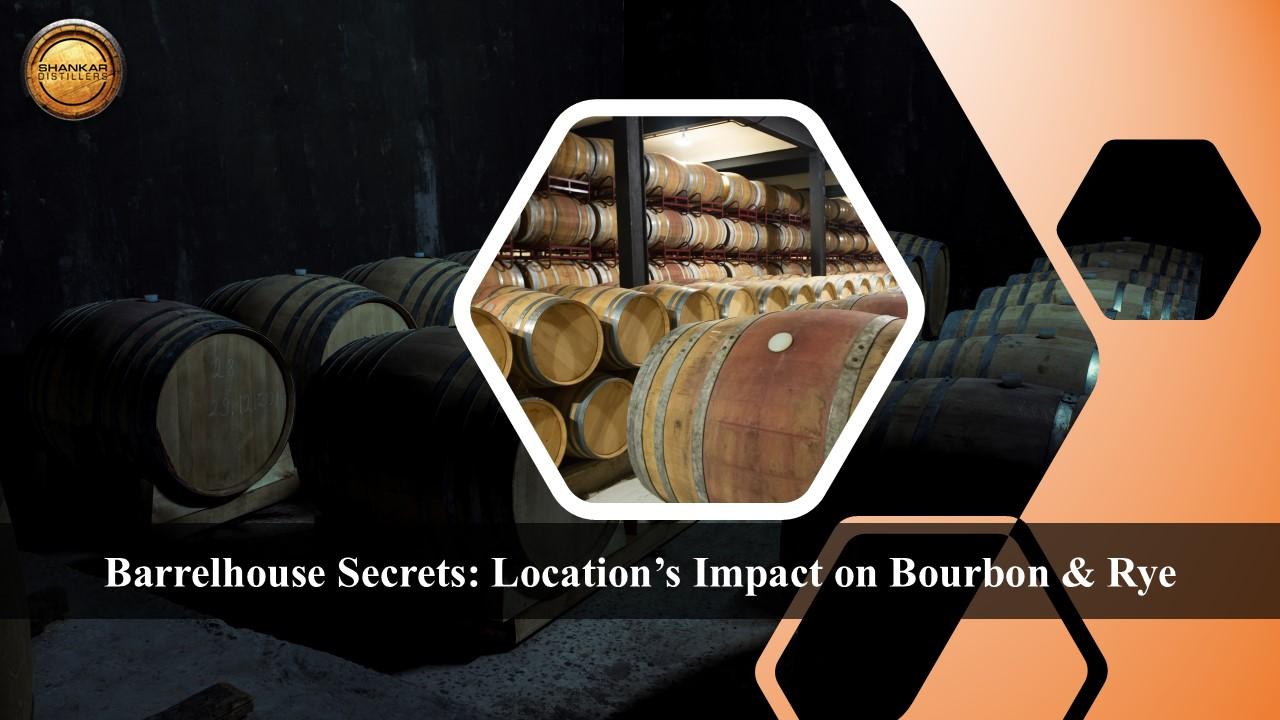

The moment a cask is rolled into a rickhouse, its destiny shifts from distillery floor to the whims of nature and architecture. Whether you are touring Shankar distillers – Premium Whiskey Distillery in USA or studying warehouse logs in Kentucky, you soon discover that the position of every barrel can steer flavour in dramatic, measurable ways. For any Premium spirits company intent on creating nuanced Straight Bourbon Whiskey and Straight Rye Whiskey, the barrelhouse is as influential as the mash bill itself.

In this deep dive we look behind the rolling rickhouse doors, examining how heat gradients, airflow paths and seasonal swings interact with oak and spirit. By the end you will understand why master blenders record exact floor, tier and rack numbers - and why two casks filled on the same day can taste decades apart.

1. The Anatomy of a Barrelhouse

Traditional American barrelhouses—also called rickhouses—are tall timber‑frame or steel structures stacked with six to nine levels of ricks. Each rack holds barrels horizontally, bung on its side, so spirit can wick through the oak’s toasted interior. Modern concrete warehouses exist, yet the classic multi‑story rickhouse remains the benchmark for Straight Bourbon Whiskey maturation because it breathes. Slatted walls and thin floors allow the building to inhale cool, moist night air and exhale warm, dry daytime heat.

2. Heat Rises: Vertical Placement Matters

Heat stratifies. Thermal studies show temperatures on an upper tier can run 10–15 °C hotter than the ground floor in midsummer. That difference accelerates extraction of lignin, hemicellulose and tannin compounds, giving high‑rack Straight Rye Whiskey a bolder profile with deeper colour. Conversely, casks resting on the bottom tier age slowly, developing softer vanilla and orchard‑fruit notes. Distillers seeking a balanced house style frequently rotate barrels between floors or practice “stack balancing” to homogenise proofs.

Because humidity also dips at altitude, alcohol‑rich vapour evaporates more readily upstairs, nudging proof upward. That is why barrels matured near roof trusses routinely finish above entry strength—a characteristic prized in many Premium spirits company single‑barrel releases.

3. Airflow and Cross‑Ventilation

Beyond heat, direction of airflow shapes maturation. Rickhouses built on knolls catch prevailing breezes, and windows or louvers create micro‑currents across rows. Good ventilation flushes out alcohol vapours, limiting mould on staves and allowing oxygen to feed oxidation reactions that convert harsh fatty acids into fruity esters. Barrels parked in dead‑air pockets, by contrast, can taste dense or reductive after long aging. Savvy warehouse managers map air paths with smoke tests and store Straight Rye Whiskey in breezy corridors to accentuate mint and dill aromatics.

4. Seasonal Shifts and Multi‑Year Cycles

The United States experiences four pronounced seasons, each writing a chapter in a barrel’s diary. Hot summers push spirit into oak pores; freezing winters contract liquid, drawing it back out loaded with caramelised sugars. But macro‑weather patterns run in multi‑year cycles as well—La Niña spells may yield cooler, wetter conditions, slightly slowing extraction for batches laid down in those years. Barrelhouse ledgers therefore reference fill season alongside fill date.

Some distillers now fit smart sensors to monitor temperature, humidity and barometric pressure in real time. Data shows that barrels on exterior walls feel sharper thermal shocks than those buried at the building’s core. Producers planning ultra‑long 12‑ to 15‑year expressions often favour interior racks to avoid excessive tannin build‑up.

5. Compass Points: North vs South Walls

In brick or concrete rickhouses, compass orientation still matters. A south‑facing side bathes in sun, delivering extra warmth; the opposite wall stays cooler and damper. Master blenders sometimes pull Straight Bourbon Whiskey from the southern tiers for robust spice, then layer in north‑wall barrels to supply creamy praline notes. Similarly, rye destined for bottled‑in‑bond bottlings may derive peppery intensity from casks aged two summers against a sun‑warmed wall before being shifted to a shaded bay for polishing.

6. The Angel’s Share and Concentration

Evaporation—poetically called the angel’s share—ranges from 2 % to 10 % annually depending on rack height and building construction. Upper tiers lose more water and alcohol, concentrating congeners and darkening colour. Lower racks retain volume but may carry more sulphury new‑make remnants. When a Premium spirits company selects single barrels, it often prizes top‑floor Straight Rye Whiskey for its viscous maple texture, while adopting low‑floor bourbon to bring orchard‑fruit lift to small‑batch blends.

7. Chemical Signatures of Location

Laboratory analyses confirm location effects. High‑rack bourbon shows elevated levels of furfural and 5‑hydroxymethyl‑furfural—markers of caramel sweetness—while low‑rack whiskey contains more oak lactones responsible for coconut and wood flavours. Likewise, rye aged in well‑ventilated zones exhibits higher ethyl ferulate concentrations, amplifying clove and anise tones.

8. Modern Innovations: Temperature‑Controlled Warehousing

Some producers now use temperature‑controlled warehouses to mimic classic rickhouse cycles with greater precision. They might run two‑week heat pulses in winter to keep esterification rolling or mist sprinkler systems in summer to temper proof rise. Even then, architects design intentional hot corners and cool cores to preserve batch diversity, recognising that complexity blooms through contrast.

9. From Rack to Glass: Sensing Location in a Sip

Visit a distillery’s Whiskey tasting rooms and you will often sample casks that share mash bills and fill dates yet reveal location fingerprints. Upper‑fourth‑tier Straight Bourbon Whiskey can burst with toasted hazelnut and dried cherry, while its ground‑level sibling leans toward honeyed pear. Rye from a windy corridor may shine with eucalyptus brightness versus the earthy cocoa of barrels kept in still corners.

10. Practical Takeaways for Collectors and Blenders

- Barrel Stamps Matter – When buying single‑barrel releases, study warehouse codes; floor, tier and rack numbers hint at flavour style.

- Rotation Strategy – For consistent batch profiles, rotate casks across tiers every few years to average out location extremes.

- Diversity Equals Flexibility – Stocking multiple warehouse designs gives a blender broader tool for future limited editions.

Conclusion

Inside every barrelhouse, nature, design and a careful measure of engineering conspire to sculpt whiskey long after distillation. Vertical heat bands drive extraction speed; airflow fosters oxidation; seasonal pressure swings create rhythmic infusions of oak sugars; and compass orientation paints nuanced gradients of spice and sweet. By mastering these invisible forces, a Premium spirits company can craft Straight Bourbon Whiskey layered with toffee depth or coax Straight Rye Whiskey toward citrus‑pepper brilliance.

As consumer palates grow more curious, transparency around rack codes and warehouse maps will deepen appreciation for the art behind the rickhouse. Whether you are a blender selecting marriage components or an enthusiast comparing private picks, remember: the next time you lift a glass, you taste not just grain and yeast, but the living climate of the barrelhouse itself.

Useful Links