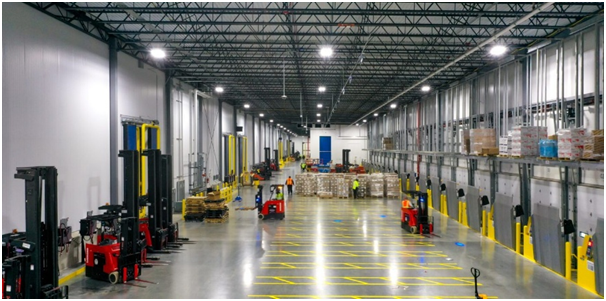

How Smart Automation Upgrades Cold Storage Efficiency And Cuts Energy Costs

If you are maintaining a cold storage facility without automation, I guess it's already bringing you lots of efficiency problems and is time-consuming, right? Although running a cold storage warehouse is complex, it gets really easier for you to manage with automation. With warehouse automation, intelligent systems run the warehouse, reducing errors and speeding up the deliveries. In this article, we are going to discuss how integrating automation can transform your cold storage operations to run smoothly, giving sustainable results.

To get more details about warehouse automation, visit https://www.instagram.com/p/DKxVtVnxFHO/?igsh=MTQwbjZteW5sYXlmag==.

Why Manual Cold Storage Operations Can Slow Down Productivity

A cold storage warehouse without automation can be challenging in moving the goods manually from the cold storage and scanning products while maintaining the low temperatures. While in the process, it is unavoidable to make human errors, such as placing products wrongly and failing to maintain optimalcooling. Automation uses smart software and sensors that help you with barcode scanning and moving the goods from cold storage to packing via robotic conveyor belts. This ultimately reduces human errors in packaging and ensures that work is done faster with productivity.

Why Smart Automation Is Key for Cold Storage Energy Efficiency

Maintaining low temperatures is the most concerning, especially in the food and pharma industry. Where food supplies and medicines need to be stored in optimal temperatures for maintaining their viability. Well, a significant amount of energy is consumed in keeping the cold storage at the right level of temperature. But with warehouse automated solutions, these costs can be reduced by managing the refrigeration systems smartly. The IoT sensors in automation will monitor the cold storage warehouse temperature and humidity constantly and automatically notify the cooling system to adjust accordingly for storage. Reducing the workforce to check on temperature maintenance conditions manually avoids huge losses of wastage and saves energy bills.

Automation also brings safety to your cold storage warehouses

Workers working in cold warehouses will always be at risk of accidents and health concerns when moving heavy pallets, and also with frequent exposure to freezing temperatures. But automation brings down this burden for these dangerous tasks by replacing them with robotic arms and automated guided vehicles that operate at high-grade precision, shutting down on workspace accidents, enhancing your cold storage warehouse safety.

About Primus:

Primus is an industrial automation company that exemplifies leading design-build automated services for cold storage. Primus has decades of experience in constructing high-performance warehouses that meet each industry's unique requirements.

To get more information, visit https://www.primusbuilders.com/.

Email: [email protected]

Contact: 7709287120

Original Source: https://bit.ly/4oBJw0F