What Factors Affect Turbine Flow Meter Performance in Industrial Systems?

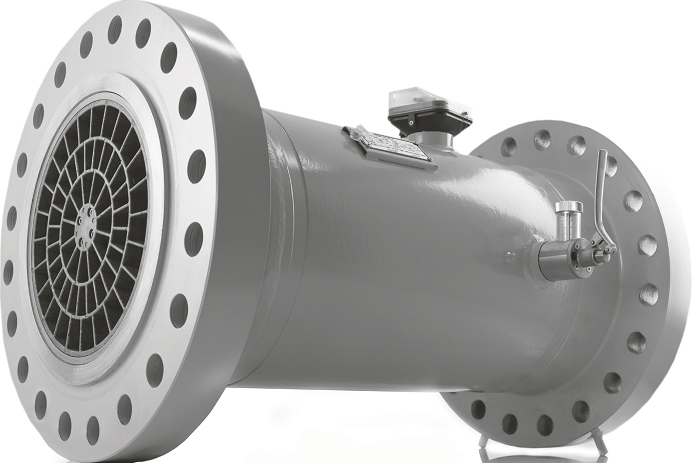

Turbine flow meters are widely used in industrial systems to measure the flow rate of liquids and gases accurately. They are valued for their reliability, fast response, and ability to operate across a broad range of flow rates. These meters use a rotating turbine wheel placed in the flow stream. As fluid passes through, it spins the turbine. The rotation speed correlates with the velocity of the fluid, which allows the flow rate to be calculated.

Despite their advantages, turbine flow meters are sensitive to a variety of factors that can influence their performance. Understanding these factors is essential for engineers and operators who rely on accurate flow measurement. Factors such as fluid properties, installation conditions, mechanical wear, and maintenance practices can significantly affect meter accuracy and longevity. This article explores the key variables that impact turbine flow meter performance in industrial systems.

Fluid properties and their impact

Viscosity and density

The viscosity and density of the fluid are critical to turbine flow meter accuracy. Viscosity affects the friction between the fluid and the turbine blades. High-viscosity fluids can slow down the turbine rotation, leading to underestimation of flow rate. Conversely, low-viscosity fluids allow the turbine to spin more freely, which can improve measurement sensitivity.

Density also plays a role in the momentum transferred to the turbine blades. Higher-density fluids provide greater force, producing faster turbine rotation at the same flow rate. Therefore, variations in fluid density can lead to errors if the meter is not properly calibrated for the specific fluid in use. Industrial operators often need to correct for these properties to maintain accurate measurements.

Temperature effects

Temperature influences both fluid properties and the mechanical components of a turbine flow meter. As temperature rises, fluid viscosity typically decreases, which can change the turbine’s rotational behavior. Extreme temperatures can also cause expansion or contraction of the meter housing and turbine components. This may alter clearances, bearing friction, or the gap between the turbine and the flow tube, which affects performance. Temperature compensation or calibration is often necessary in systems that experience large thermal variations.

Presence of suspended solids

Suspended particles in the fluid can damage the turbine or reduce its responsiveness. Abrasive solids may erode blades or bearings, leading to increased friction and slower rotation. Accumulation of non-abrasive solids can also disrupt flow patterns and reduce accuracy. In industrial systems where slurry or particulate-laden fluids are common, pre-filtration is recommended to protect the turbine flow meter and ensure reliable readings.

Installation and flow conditions

Straight pipe requirements

Turbine flow meters are sensitive to the flow profile entering the meter. Uneven or turbulent flow can affect the rotation of the turbine and reduce measurement accuracy. Most manufacturers recommend a minimum length of straight pipe upstream and downstream of the meter. This ensures a fully developed flow profile and reduces disturbances caused by bends, valves, or other fittings. Failure to meet these requirements can introduce systematic errors.

Alignment and orientation

Proper alignment of the turbine flow meter within the pipeline is essential. The meter must be installed in line with the flow direction, and any misalignment can increase bearing friction or create vortices that affect rotation. Vertical or horizontal orientation should also follow manufacturer guidelines. Some meters are sensitive to the orientation of the turbine relative to the flow, and incorrect positioning can reduce accuracy or lead to premature wear.

Pulsating or unsteady flow

Turbine flow meters perform best under steady flow conditions. Pulsating flow, common in reciprocating pumps or compressors, can cause the turbine to accelerate and decelerate repeatedly. This results in fluctuating readings and potential mechanical stress on the bearings. In such cases, dampening devices or pulsation-absorbing sections may be required to stabilize the flow before it reaches the meter.

Mechanical factors affecting performance

Bearing condition

The bearings in a turbine flow meter support the rotation of the turbine wheel. Over time, they can wear out or become contaminated, increasing friction. Higher friction reduces rotational speed and can cause underestimation of flow rates. Regular inspection and lubrication of bearings are necessary to maintain accuracy, especially in high-flow or abrasive fluid systems.

Turbine blade wear

Turbine blades are exposed to constant contact with flowing fluid. Erosion, corrosion, or deformation of the blades can alter the angular momentum transferred from the fluid to the turbine. Worn blades reduce sensitivity and may lead to inaccurate readings. Industrial operators often schedule periodic calibration and replacement of turbine elements to ensure optimal performance.

Meter calibration and signal processing

Turbine flow meters rely on a signal generated by the rotating turbine. Magnets, coils, or optical sensors detect rotation and convert it into a flow rate signal. Any misalignment or degradation of the sensor can affect measurement accuracy. Regular calibration of both the turbine and the sensing electronics is essential. This ensures that signal processing accurately reflects the true flow rate.

Maintenance and environmental considerations

Contamination and fouling

Industrial fluids often contain oils, residues, or deposits that can foul the turbine or bearings. Fouling increases friction and can create hysteresis in readings, where the meter responds differently to increasing versus decreasing flow. Regular cleaning and monitoring are required to prevent contamination from degrading performance.

Corrosion and material compatibility

The materials used for turbine flow meters must be compatible with the fluid and environmental conditions. Corrosive fluids or aggressive chemicals can degrade the turbine, housing, or bearings. Using stainless steel, specialized alloys, or protective coatings helps extend meter life. Monitoring for corrosion is especially important in chemical processing, wastewater, and petrochemical industries.

Vibration and mechanical stress

Industrial pipelines often experience vibrations from pumps, compressors, or other equipment. Excessive vibration can affect turbine rotation and may loosen bearings or mountings. Proper mechanical support, vibration isolation, and careful system design help prevent these issues. Continuous monitoring of meter performance can indicate whether vibration is affecting accuracy.

Conclusion

Turbine flow meters are reliable instruments for measuring fluid flow in industrial systems, but their performance depends on multiple factors. Fluid properties such as viscosity, density, temperature, and suspended solids directly influence turbine rotation and measurement accuracy. Installation conditions, including straight pipe requirements, alignment, and flow stability, are critical to obtaining precise readings. Mechanical factors like bearing condition, blade wear, and sensor calibration also determine long-term performance.

Maintenance practices, environmental conditions, and compatibility with the fluid further affect reliability. Regular inspection, cleaning, calibration, and careful material selection help ensure that turbine flow meters operate accurately and efficiently over time. Understanding these factors allows engineers to design systems that maximize meter performance and extend operational life.

By addressing these variables, industrial operators can ensure that turbine flow meters provide dependable flow measurements, reduce errors, and support optimal process control. Proper attention to fluid characteristics, installation, mechanical integrity, and environmental conditions creates a foundation for accurate and sustainable flow measurement in industrial applications.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness