How Does Fluid Viscosity Impact an Orifice Plate Flow Meter Reading?

The orifice plate flow meter is one of the most widely used devices for measuring flow in industrial processes. Its simple design, reliability, and cost-effectiveness make it a standard choice for gas, liquid, and steam measurement. However, accuracy depends on several factors, and one of the most critical is fluid viscosity. Viscosity influences the velocity profile, pressure drop, and flow coefficient, which all affect the meter’s performance. Understanding how viscosity interacts with the principles of orifice plate measurement is essential for accurate readings and proper application.

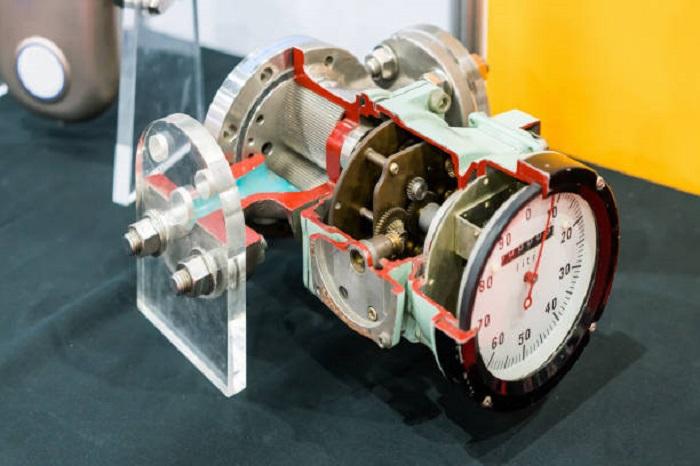

Understanding the Orifice Plate Flow Meter

Basic Principle of Operation

An orifice plate flow meter operates on the principle of differential pressure measurement. The plate, with a central bore, creates a restriction in the pipeline. As fluid passes through the orifice, velocity increases, and pressure decreases. By measuring the pressure difference upstream and downstream, the flow rate can be calculated using established equations. These calculations are based on fluid dynamics principles and assume ideal conditions.

Assumptions in Standard Calculations

The standard orifice plate equations assume steady, incompressible flow with a uniform velocity profile. They also assume that the fluid behaves as a Newtonian liquid or gas with predictable properties. These assumptions simplify calculations but can be challenged by variations in viscosity. When fluid viscosity changes, deviations in the velocity distribution and energy losses occur, leading to differences between actual and theoretical flow rates.

The Concept of Fluid Viscosity

Definition of Viscosity

Viscosity is a measure of a fluid’s resistance to flow. High-viscosity fluids, such as heavy oils, resist motion and flow more slowly. Low-viscosity fluids, such as water or natural gas, flow more freely. Viscosity directly affects the frictional forces within a fluid and between the fluid and pipe walls. It is usually expressed in centipoise (cP) or pascal-seconds (Pa·s).

Viscosity and Flow Regimes

Viscosity plays a key role in determining whether a flow is laminar or turbulent. The Reynolds number, a dimensionless parameter, indicates the flow regime by combining fluid velocity, density, diameter, and viscosity. Laminar flow occurs at low Reynolds numbers, while turbulent flow dominates at higher Reynolds numbers. Because the orifice plate flow meter relies on predictable flow patterns, any change in flow regime caused by viscosity directly affects accuracy.

Impact of Viscosity on Orifice Plate Flow Meter Readings

Velocity Profile Distortion

In an ideal scenario, fluid velocity increases sharply through the orifice, creating a measurable pressure drop. High viscosity, however, alters the velocity profile by increasing frictional resistance. This distortion changes how fluid accelerates through the orifice, which can lead to lower pressure drops than predicted. As a result, the orifice plate flow meter may underestimate the flow rate when dealing with viscous fluids.

Pressure Loss Effects

Viscous fluids cause greater energy losses due to friction. The pressure recovery downstream of the orifice is reduced, leading to a higher permanent pressure loss. Since the flow calculation depends on an accurate correlation between differential pressure and velocity, these additional losses reduce measurement accuracy. In applications where energy efficiency is critical, the added pressure loss becomes both a measurement and process concern.

Influence on Discharge Coefficient

The discharge coefficient is a correction factor used to relate theoretical flow equations to real-world conditions. It accounts for flow contraction, friction, and turbulence around the orifice. Fluid viscosity directly influences the discharge coefficient by changing flow separation and turbulence patterns. For low-viscosity fluids under turbulent conditions, the coefficient remains stable. For high-viscosity fluids, especially in laminar or transitional regimes, the coefficient deviates significantly, leading to miscalculations.

Practical Examples of Viscosity Impact

Low-Viscosity Fluids

When measuring gases or light liquids, viscosity has minimal effect. The flow is typically turbulent, and the velocity distribution across the pipe remains close to the assumed profile. In such cases, an orifice plate flow meter delivers reliable readings with standard calibration constants.

Medium-Viscosity Fluids

With fluids such as kerosene or light oils, viscosity begins to influence the Reynolds number. Transitional flow regimes may occur, where neither laminar nor fully turbulent flow dominates. In these cases, orifice plate readings may drift from true flow values unless discharge coefficients are adjusted. Engineers often rely on empirical calibration to improve accuracy.

High-Viscosity Fluids

In heavy oils or polymer solutions, viscosity has a dramatic effect. Flow becomes laminar, the velocity profile flattens, and energy losses increase sharply. Under these conditions, an orifice plate flow meter can produce significant errors, sometimes exceeding acceptable industry limits. Specialized flow measurement methods, such as positive displacement meters or Coriolis meters, are often preferred for very viscous fluids.

Methods for Managing Viscosity Effects

Calibration Adjustments

One practical solution is to calibrate the orifice plate flow meter under actual operating conditions. By establishing a discharge coefficient specific to the process fluid, operators can correct for viscosity-related deviations. This approach provides greater accuracy but requires careful testing.

Use of Standards and Guidelines

International standards, such as ISO 5167, provide guidance for applying orifice plates with different fluids. These standards include correction factors for Reynolds number and viscosity effects. Engineers must follow these recommendations to ensure reliable measurement.

Alternative Measurement Technologies

When viscosity severely compromises accuracy, alternative flow meters may be more cost-effective. Positive displacement meters measure volumetric flow regardless of viscosity, while Coriolis meters directly measure mass flow without depending on fluid properties. These instruments, though often more expensive, may provide better performance in demanding applications.

Broader Implications of Viscosity on Flow Measurement

Economic Impact

Errors in flow measurement caused by viscosity can have financial consequences. Underestimating flow can lead to product loss, while overestimating flow can affect billing and reporting. Accurate measurement ensures fair trade, process efficiency, and regulatory compliance.

Process Efficiency

Viscosity-related inaccuracies can affect process control. For example, in chemical dosing or energy monitoring, precise flow data is essential. Poor readings from an orifice plate flow meter may lead to inefficient operations, wasted resources, or compromised product quality.

Safety and Compliance

In industries handling hazardous fluids, incorrect flow measurement may compromise safety. Accurate readings ensure that pressure levels, flow rates, and system performance remain within safe limits. Viscosity must therefore be carefully considered when selecting orifice plate meters for critical applications.

Conclusion

The effect of fluid viscosity on an orifice plate flow meter is significant, particularly when dealing with medium to high-viscosity fluids. Viscosity alters the velocity profile, increases energy losses, and influences the discharge coefficient, all of which can lead to measurement errors. While low-viscosity fluids produce reliable readings, higher viscosity requires calibration adjustments or even alternative flow measurement technologies. Understanding viscosity’s role is essential for engineers, as it affects not only measurement accuracy but also economic efficiency, process control, and safety. For industries seeking precise and reliable flow data, accounting for fluid viscosity is not optional but a necessary step in effective instrumentation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness