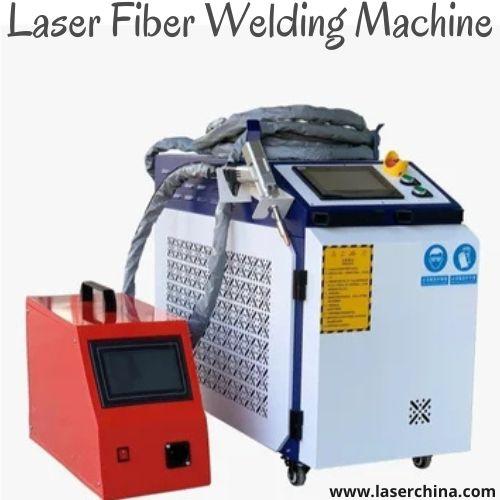

Laser Fiber Welding Machine for High Precision Welding Across Industrial Manufacturing Applications

The laser fiber welding machine is transforming the way industries approach modern welding requirements. With the growing demand for efficiency, accuracy, and durability in welded components, this technology has become a crucial solution across multiple fields. Manufacturers are turning to this advanced system because it addresses the pressing need for cleaner welds, reduced processing times, and seamless integration into existing production lines.

From automotive assembly to aerospace engineering, the laser fiber welding machine stands as a practical tool that ensures consistency where traditional welding often struggles. It is not just about replacing old systems; it is about reshaping the future of welding with a method that aligns with today’s industrial standards.

Evolution of Welding in Manufacturing

Traditional welding has served industries for decades, but increasing production demands have highlighted its limitations. Conventional processes often require more post-treatment, consume higher amounts of energy, and leave room for errors. The introduction of the laser fiber welding machine represents a significant step forward.

Its design ensures that industries can work with complex materials while maintaining reliability. Unlike older welding techniques, this technology minimizes distortion, ensures deeper penetration, and delivers smooth weld seams. The progression from manual processes to automated, laser-based systems is part of a wider movement toward industrial modernization.

Why Industries Adopt the Laser Fiber Welding Machine

The need for precision has never been more critical. Components in modern vehicles, aircraft, and electronics are manufactured with tighter tolerances. In such cases, even small deviations can affect overall performance. The laser fiber welding machine is specifically developed to respond to these challenges.

It allows industries to work with stainless steel, aluminum, titanium, and other metals without compromising on quality. Its ability to handle different thicknesses and produce strong, clean welds ensures reliability across diverse projects. Industries that aim for consistent output find this machine particularly valuable.

Applications Across Sectors

One of the most important aspects of the laser fiber welding machine is its wide adaptability.

-

Automotive Manufacturing

In vehicle production, where precision and speed matter, laser fiber welding plays a central role in assembling components such as fuel systems, exhausts, and structural parts. It ensures leak-proof joints and durable assemblies that withstand long-term usage. -

Aerospace Industry

In aviation, safety and performance are priorities. The laser fiber welding machine contributes to creating strong joints in turbine components, hydraulic systems, and lightweight structural parts. The reliability it offers supports strict aerospace standards. -

Electronics and Electrical Equipment

Miniaturization in electronics requires welding that does not damage delicate parts. The machine delivers fine welds on small components, making it suitable for circuit connections, battery systems, and sensor integration. -

Medical Devices

In healthcare manufacturing, materials like titanium and stainless steel require specialized welding. The laser fiber welding machine is applied in producing surgical instruments, implants, and diagnostic equipment with precision and hygiene in mind. -

Energy and Power Systems

Whether in renewable energy or conventional power setups, welding forms the backbone of component assembly. This machine supports the production of energy-efficient systems by ensuring durability in pipelines, generators, and structural parts.

Impact on Production Efficiency

Efficiency is at the heart of industrial success. The laser fiber welding machine contributes to shorter cycle times and higher throughput. Since it requires minimal post-weld processing, production lines remain smooth and cost-effective.

Its automation potential also reduces dependency on manual labor, allowing operators to supervise multiple processes simultaneously. This not only increases productivity but also enhances workplace safety, as operators maintain a safe distance from the welding arc.

Technological Integration

Modern factories thrive on automation and digital control. The laser fiber welding machine fits seamlessly into automated systems, including robotic arms and computer-controlled production lines. It is adaptable to Industry 4.0 environments, where monitoring, data tracking, and predictive maintenance play important roles in minimizing downtime.

By integrating into existing processes, it becomes a long-term solution rather than a temporary tool. This adaptability makes it suitable for both small-scale workshops and large manufacturing plants.

Cost Considerations in Industrial Use

While the laser fiber welding machine may require an initial investment, industries often evaluate its benefits over time. Reduced rework, higher accuracy, and faster production rates justify its role in large-scale manufacturing. Its long-term cost efficiency is one of the main reasons why many companies see it as an essential part of their production strategy.

Environmental Considerations

Sustainability is becoming central to industrial decision-making. The laser fiber welding machine supports this by reducing waste material and minimizing energy usage compared to older welding systems. With cleaner processes and fewer consumables, it aligns with eco-friendly practices that industries are adopting worldwide.

Training and Workforce Adaptation

The integration of advanced welding systems often requires workforce training. However, the laser fiber welding machine is designed with user-friendly controls that allow skilled operators to adapt quickly. Companies that invest in training programs ensure their workforce can maximize machine performance while maintaining safety and consistency.

Global Demand and Market Growth

The demand for the laser fiber welding machine continues to rise across global markets. Industrial sectors in Asia, Europe, and North America are adopting it as part of their modernization strategies. With manufacturing moving toward higher standards of precision, the growth of this technology is expected to continue.

Companies seeking to maintain a competitive edge view it not as an option but as a necessity. The shift is not limited to large corporations; even mid-sized manufacturers are investing in this system to meet customer demands.

Future of Welding Technology

The laser fiber welding machine represents not only today’s needs but also the future of industrial welding. With ongoing advancements in laser power, beam control, and material adaptability, the technology is set to expand further. Future developments are expected to bring even more compact designs, greater efficiency, and integration with advanced robotics.

Industries that adopt the system now position themselves ahead in meeting future market requirements.

Final Thoughts

The laser fiber welding machine is more than just equipment; it is a foundation for modern industrial growth. By providing precision, efficiency, and adaptability across multiple sectors, it has become a vital part of global manufacturing. As industries continue to demand higher standards, this technology proves to be a reliable solution that delivers consistent performance while supporting future advancements.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness