How to Troubleshoot Pressure Loss in an Orifice Plate Flow Meter Pipeline?

Flow measurement is an important part of industrial processes. Orifice plate flow meters are among the most commonly used instruments for this purpose. They are simple, inexpensive, and reliable. However, one recurring challenge in pipelines using orifice plates is pressure loss. While some level of pressure drop is expected due to the design of the meter, excessive pressure loss can cause operational problems. Troubleshooting this issue requires a clear understanding of how the device works, what causes problems, and how to address them effectively.

Understanding Pressure Loss in Orifice Plate Flow Meters

How the Orifice Plate Creates Pressure Drop

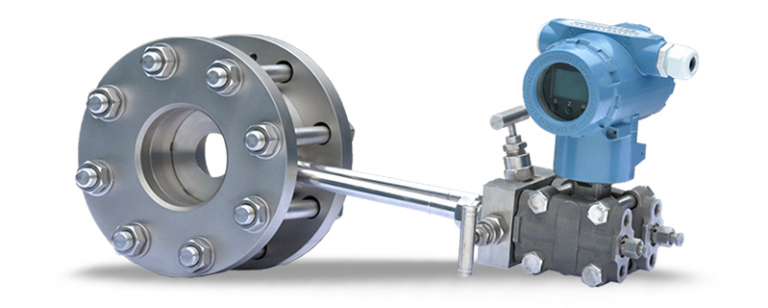

An orifice plate is a thin metal plate with a hole in the center. When fluid flows through the hole, velocity increases and pressure decreases. This pressure difference is used to calculate the flow rate. However, not all of the lost pressure is recovered downstream. Some of it becomes permanent pressure loss, which is an inherent characteristic of orifice plate flow meters.

Why Pressure Loss Matters

In a pipeline system, excessive pressure loss reduces efficiency. Pumps must work harder to maintain flow, which increases energy costs. In severe cases, low pressure downstream can affect the performance of connected equipment. Troubleshooting pressure loss is therefore essential to ensure smooth operation.

Common Causes of Excessive Pressure Loss

Plate Damage or Wear

Over time, the sharp edges of the orifice plate may wear down. Erosion caused by high velocity fluids or abrasive particles can change the shape of the hole. A damaged plate creates turbulence, which increases pressure loss.

Incorrect Plate Sizing

If the hole in the orifice plate is too small for the flow, the restriction becomes severe. This results in an excessive pressure drop. Proper sizing is critical during installation to balance measurement accuracy with acceptable energy loss.

Build-Up of Deposits

Pipelines carrying dirty or contaminated fluids may develop deposits on the plate. Scale, corrosion products, or dirt can narrow the opening and increase pressure loss. In some cases, the deposits create irregular flow patterns that worsen the problem.

Poor Installation

Improper installation is another common cause. Misaligned plates or insufficient straight pipe lengths upstream and downstream can cause turbulence. Turbulence interferes with pressure recovery and adds to the loss.

Troubleshooting Techniques

Inspecting the Orifice Plate

The first step is to remove and inspect the orifice plate. Look for signs of wear, erosion, or damage. If the edges are rounded or if the hole has deformed, the plate should be replaced. A clean and sharp edge is necessary for accurate readings and minimal turbulence.

Checking for Deposits

Inspect both the plate and the surrounding pipeline for dirt, scale, or corrosion deposits. If buildup is found, the system should be cleaned. Routine maintenance schedules can help prevent recurring issues.

Verifying Installation Requirements

Confirm that the meter is installed correctly. This includes checking the alignment of the plate, ensuring that pressure taps are properly located, and verifying that sufficient straight pipe runs are present. If the installation does not follow standards, pressure loss is likely to be higher than expected.

Reviewing Plate Sizing

If the orifice plate is too restrictive, resizing may be necessary. Engineers should recalculate the bore diameter based on the actual flow requirements. Choosing a larger bore can reduce unnecessary pressure loss while still providing accurate measurements.

Preventing Future Problems

Regular Maintenance

Routine inspection and cleaning of the plate and pipeline reduce the chances of pressure loss caused by deposits or wear. Maintenance should be part of the overall flow meter management plan.

Material Selection

For fluids containing abrasive or corrosive particles, selecting a durable material for the orifice plate is important. Stainless steel, Monel, or hardened alloys may resist damage better than standard carbon steel.

Monitoring Flow Conditions

Monitoring the condition of the flow, such as velocity, temperature, and cleanliness, helps in predicting potential issues. If the operating conditions change, the orifice plate may need to be recalibrated or resized.

Comparing with Other Flow Meter Technologies

Orifice Plate Versus Thermal Mass Flow Meters

While orifice plates are widely used, newer technologies such as thermal mass flow meters offer some advantages in certain situations. Thermal mass flow meters do not rely on pressure differential. Instead, they measure the heat transfer caused by gas flow. This eliminates the issue of permanent pressure loss. For low flow gas applications, thermal mass flow meters can be more efficient. However, orifice plates remain superior in high pressure, high temperature, and liquid measurement scenarios.

Orifice Plate Versus Coriolis Flow Meters

Coriolis meters also measure mass flow directly and provide excellent accuracy. They do not cause significant pressure loss. The limitation is their higher cost and sensitivity to pipeline vibration. Orifice plates continue to be favored where cost and durability are priorities.

Orifice Plate Versus Venturi Tubes

Venturi meters, like orifice plates, use a constriction to measure flow. However, they are designed to recover pressure more effectively. While they reduce permanent pressure loss, they are larger and more expensive to install. Orifice plates remain the more practical choice in many cases.

Practical Example

A Refinery Pipeline Scenario

Consider a refinery pipeline transporting crude oil. The orifice plate installed years earlier begins to show signs of wear. Operators notice higher than expected pressure loss, leading to increased pumping costs. Upon inspection, they discover erosion at the edges of the plate due to abrasive particles in the crude oil. By replacing the worn plate with one made of a stronger alloy and ensuring proper installation, the refinery reduces pressure loss. This improves efficiency and lowers energy consumption.

This scenario illustrates how timely troubleshooting and corrective action can restore system performance. It also highlights the importance of selecting the right material and maintaining the plate regularly.

The Future of Orifice Plate Systems

Integration with Digital Tools

While the orifice plate is a mechanical device, it is often paired with modern transmitters and data acquisition systems. This integration allows real-time monitoring of pressure differentials and helps detect unusual losses quickly.

Role in Modern Industry

Even as advanced devices like thermal mass flow meters become popular, orifice plate flow meters continue to serve in heavy industries. Their simplicity, low cost, and durability ensure that they will remain relevant. With proper troubleshooting and maintenance, they can operate efficiently for decades.

Conclusion

Troubleshooting pressure loss in an orifice plate flow meter pipeline requires a systematic approach. Common causes include plate wear, incorrect sizing, deposits, and poor installation. The solution lies in regular inspection, proper maintenance, correct sizing, and good installation practices. While other technologies such as thermal mass flow meters avoid the issue of permanent pressure loss, the orifice plate remains a trusted instrument for many applications. By balancing tradition with modern practices, industries can ensure efficient and reliable flow measurement.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness