How Does Pipe Diameter Influence Turbine Flow Meter Accuracy?

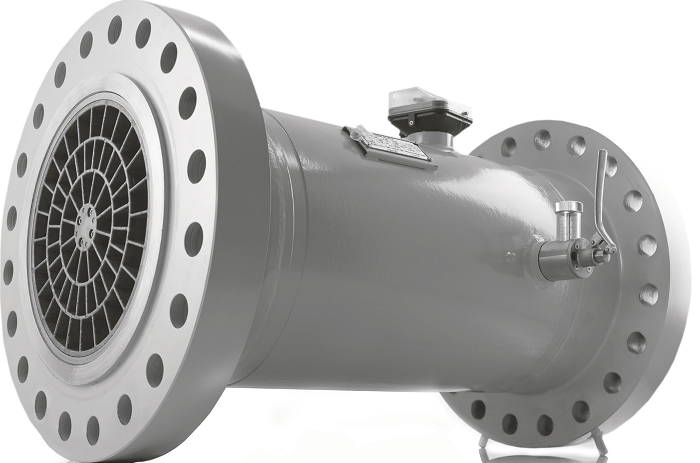

A Turbine Flow Meter is widely recognized for its precision in measuring fluid flow in industries such as oil and gas, water management, and chemical processing. These instruments rely on a rotor that spins proportionally to the velocity of the fluid passing through the pipe. The rotational speed is then converted into a flow rate. While the principle is straightforward, many factors influence accuracy. Among these factors, pipe diameter plays a critical role. If the diameter is not properly matched to the flow meter’s specifications, the performance of the instrument can decline, leading to measurement errors and inefficiencies in operations.

To understand how pipe diameter affects a turbine flow meter, it is essential to look at the relationship between fluid velocity, turbulence, and the meter’s design. The interaction of these variables helps explain why selecting the correct pipe size is central to ensuring reliable results.

Fundamentals of Turbine Flow Measurement

How the Meter Operates

A turbine flow meter functions on the principle of fluid dynamics. As fluid enters the meter body, it strikes the rotor blades. The rotor spins at a rate proportional to the flow velocity. Sensors then detect the rotational speed and convert it into electrical pulses, which are translated into flow rate readings. Accuracy is determined by how consistently the rotor translates velocity into measurable signals.

The Role of Fluid Velocity

Pipe diameter directly influences fluid velocity. In a larger pipe, for the same volumetric flow, the velocity decreases because the fluid has more space to travel. In a smaller pipe, the velocity increases because the same volume is constrained. Since turbine flow meters depend on rotor movement driven by velocity, any change caused by pipe diameter will directly impact performance.

Influence of Pipe Diameter on Accuracy

Oversized Pipes and Under-Range Readings

When a turbine flow meter is installed in a pipe that is too large for the expected flow rates, the velocity of the fluid may drop below the meter’s optimal operating range. The rotor may not spin consistently, leading to underestimation of flow. In extreme cases, the meter may fail to register flow at all, especially during low demand periods. This scenario highlights the importance of maintaining a balance between pipe size and expected volumetric flow.

Undersized Pipes and Over-Range Stress

On the other hand, installing a turbine flow meter in a pipe that is too small can cause the velocity to rise above recommended levels. Excessive velocity introduces turbulence, accelerates wear on the rotor blades, and can result in overestimation of flow. Long-term exposure to high velocity conditions may also damage the meter mechanically, reducing its lifespan and reliability.

Fluid Dynamics and Turbulence

The Impact of Flow Profile

Pipe diameter also shapes the flow profile. In an ideal situation, fluid should flow smoothly in a fully developed laminar or mildly turbulent pattern when it reaches the turbine. If the diameter creates conditions that encourage turbulence, the rotor experiences inconsistent forces. This irregular motion reduces accuracy by introducing noise into the measurement signals.

Straight Pipe Requirements

To ensure accuracy, turbine flow meters often require a specific length of straight pipe upstream and downstream. These lengths allow the flow profile to stabilize before reaching the meter. When pipe diameter is poorly matched, longer straight lengths may be necessary to compensate for distorted profiles. This requirement increases installation complexity and cost.

Practical Applications and Case Studies

Oil and Gas Industry

In oil pipelines, where turbine flow meters are used for custody transfer, accuracy is critical. Even small deviations due to improper pipe sizing can lead to financial losses. For instance, a meter installed in a pipe with a diameter too wide for the expected flow rates may under-register delivered volumes. This discrepancy affects billing, compliance, and trust between parties.

Water Distribution Systems

In municipal water systems, turbine flow meters are installed to monitor distribution efficiency. Pipes with mismatched diameters often result in readings that fail to capture low-flow events. Undetected losses or leaks can persist, wasting resources and undermining infrastructure planning.

Chemical Processing Plants

In chemical plants, precise measurement is required for blending and dosing. A turbine flow meter placed in an undersized pipe may accelerate chemical erosion of the rotor due to high velocity. This not only reduces meter accuracy but also introduces contamination risks to sensitive processes.

Calibration and Compensation Techniques

Factory Calibration

Most turbine flow meters are calibrated under controlled conditions that assume optimal pipe diameter and flow profile. When installed in the field, deviations in pipe size can cause performance to diverge from factory settings. Regular recalibration or correction factors must be applied to account for the real-world impact of pipe diameter.

Use of Flow Conditioners

Flow conditioners can be installed to reduce turbulence caused by diameter mismatches. These devices straighten and stabilize fluid flow before it enters the turbine meter. While helpful, they add cost and complexity to installations. Properly matching pipe diameter to the meter is generally more efficient than relying solely on conditioners.

Long-Term Effects of Diameter on Maintenance

Wear and Tear on Components

When pipe diameter increases fluid velocity beyond the recommended range, the rotor and bearings of a turbine flow meter experience accelerated wear. This leads to higher maintenance frequency, unplanned downtime, and increased costs over the lifetime of the instrument.

Service Life and Replacement

A well-sized pipe ensures that the turbine operates within its design limits, preserving accuracy and extending service life. Conversely, persistent mismatches in diameter shorten operational life, making frequent replacement necessary. Over time, this negates any upfront savings from using existing pipe configurations without proper assessment.

Future Considerations

Integration with Smart Systems

Modern turbine flow meters are often integrated with digital monitoring systems that can detect when readings deviate from expected ranges. If pipe diameter issues distort accuracy, these systems may trigger alarms or initiate recalibration processes. The adoption of such smart systems provides a safeguard against errors introduced by poor installation practices.

Design Improvements

As flow meter technology advances, some turbine designs are becoming less sensitive to pipe diameter variations. Enhanced rotor geometries and digital signal processing allow meters to tolerate more diverse conditions. However, even with these innovations, correct pipe sizing remains a fundamental requirement for achieving optimal accuracy.

Conclusion

Pipe diameter plays a decisive role in determining the accuracy and reliability of a turbine flow meter. Both oversized and undersized pipes create conditions that compromise readings by altering fluid velocity and flow profiles. These mismatches lead to underestimation, overestimation, or mechanical stress on the device. Industries that depend on precise flow measurement must therefore give careful attention to pipe sizing when installing turbine flow meters. By aligning the meter’s design with the application’s flow and pipe conditions, operators can ensure long-term accuracy, reduce maintenance, and enhance efficiency.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness