Understanding the Different Types of Ball Bearings

Introduction

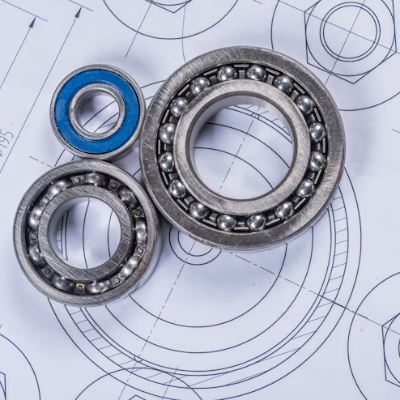

When it comes to mechanical engineering and precision machinery, types of ball bearings play a vital role in reducing friction and enabling smooth motion between parts. Whether you’re working in automotive, aerospace, manufacturing, or even electronics, knowing the right types of ball bearings can help you choose the best solution for your specific application.

Exploring the Main Types of Ball Bearings

Ball bearings are essential components designed to handle radial and axial loads. They work by using balls to separate bearing races, reducing surface contact and friction across moving parts. Let’s break down some common types of ball bearings and understand their unique features.

Deep Groove Ball Bearings

One of the most widely used types of ball bearings is the deep groove ball bearing. These bearings are designed to handle both radial and moderate axial loads, making them versatile across many industries. Deep groove ball bearings are known for their simple design, low maintenance needs, and high-speed capabilities.

Applications include electric motors, pumps, and household appliances. The deep grooves allow the bearings to accommodate misalignment and handle loads efficiently, making them a go-to choice for many standard applications.

Miniature and Thin-Wall Ball Bearings

When space is limited, miniature and thin-wall bearings become essential. These types of ball bearings are crafted for precision and are typically used in applications like medical devices, robotics, and small electronic gadgets.

Miniature ball bearings are particularly effective in high-precision tasks where compact size and low noise are critical. Thin-wall bearings, on the other hand, provide a lightweight solution without sacrificing load-carrying capacity, making them ideal for lightweight and space-sensitive designs.

Electrically Insulated Ball Bearings

A more specialized category among the types of ball bearings is electrically insulated bearings. These bearings are designed with special coatings or ceramic layers that prevent electrical current from passing through. This feature is crucial in electric motors, especially in applications where stray currents can cause damage to bearing surfaces and lead to premature failure.

Electrically insulated ball bearings help extend the service life of equipment by preventing electrical erosion, improving reliability, and reducing maintenance costs.

Conclusion

Understanding the different types of ball bearings — whether it’s deep groove, miniature, thin-wall, or electrically insulated — is key to selecting the right bearing for your machinery. Each type offers unique benefits tailored to specific operational needs, helping ensure optimal performance, durability, and efficiency. By choosing the correct types of ball bearings, industries can achieve smoother operations, lower friction, and extended equipment life.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness