Global Industrial Boiler Market

Market Estimation & Definition

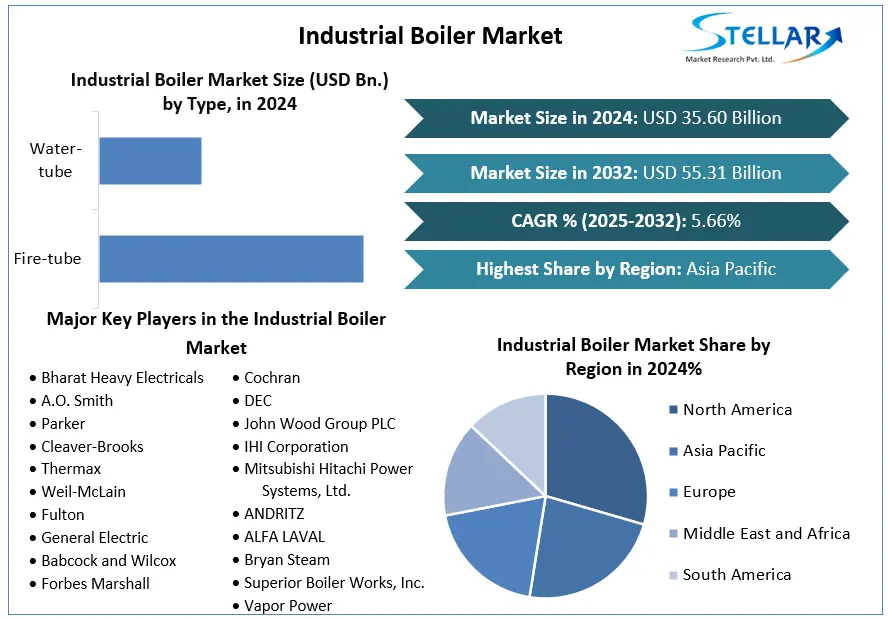

The industrial boiler market comprises complex equipment used in industrial processes to generate steam or hot water through burning fuel (natural gas, oil, coal or biomass) or via heat recovery systems. These boilers serve widely across sectors including chemicals & petrochemicals, metals & mining, food & beverages, paper & pulp, and other heavy-industry applications. According to the report, the global industrial boiler market was valued at approximately USD 35.60 billion in 2024, and is projected to grow to around USD 55.31 billion by 2032, representing a compound annual growth rate (CAGR) of about 5.66% from 2025 to 2032.

This definition covers boilers by type (fire-tube, water-tube), by technology (condensing vs non-condensing), by fuel type (natural gas, oil, coal, others) and by application. The industrial boiler is critical infrastructure for process industries, heating systems, power generation support and manufacturing operations.

Requset Free Sample Report:https://www.stellarmr.com/report/req_sample/Industrial-Boiler-Market/339

Market Growth Drivers & Opportunity

Several strong drivers are underpinning growth in the industrial boiler market:

-

Rapid industrialisation and infrastructure development: As emerging economies expand manufacturing, power generation and process industries, demand for large-scale boiler systems rises. The report emphasises that industries such as chemicals & petrochemicals lead boiler usage.

-

Energy-efficiency regulations & emission controls: Stricter environmental standards globally are pushing companies to upgrade legacy boilers with more efficient, condensing or low-emission models. The report notes advanced technology adoption as a growth factor.

-

Shift to cleaner fuels: Natural gas and newer fuel-technologies (biomass, waste-heat recovery) are becoming more prevalent, driving boiler replacement/upgrade cycles. The fuel segment for natural gas is expected to lead.

-

After-market services, maintenance & retrofit demand: Many boilers installed decades ago are reaching end-of-life or require upgrades; services for maintenance, retrofit, monitoring and replacement represent opportunities.

These drivers translate into both volume opportunities (new installations) and value opportunities (premium, efficient units, services). Manufacturers, integrators and service providers can capitalise in retrofit markets, emerging geographies (Asia-Pacific) and higher-end efficient boiler systems.

What Lies Ahead: Emerging Trends Shaping the Future

Looking to the future, the report identifies several trends shaping the industrial boiler market:

-

Water-tube boilers dominating high-pressure/high-capacity demand: The report indicates the water-tube segment held approximately 60% share in 2024 and is expected to grow at about 6.5% CAGR over the forecast period.

-

Condensing technology gaining share: Boilers adopting condensing technology (which recovers more heat) are increasingly adopted to meet efficiency and regulatory demands.

-

Regional leadership in Asia-Pacific: The Asia-Pacific region (including China, India) is expected to exhibit the highest growth due to industrial growth, urbanisation and energy-demand expansion.

-

Fuel-transition and modular designs: Transition toward natural-gas, biomass or hybrid fuel boilers, as well as modular, compact solutions for retrofit or smaller-scale plants, are emerging.

-

Digitalisation and IoT integration: While not explicitly detailed in the summary, service aftermarket trends and retrofit cycles imply increasing interest in smart monitoring, diagnostics and predictive maintenance for boiler fleets.

On the flip side, the report highlights restraints: high capital cost, logistics and installation complexity especially in remote locations, and the continued competition from alternate heat technologies.

Together, these trends suggest the market is moving from simple replacement to value-added systems (efficient, fuel-flexible, smart) and regions with high growth potential.

Segmentation Analysis

The report provides detailed segmentation:

-

By Type: Fire-tube boilers and Water-tube boilers. The water-tube type dominates (~60% share in 2024) and is forecast to grow faster.

-

By Application/End-User: Chemicals & Petrochemicals (largest segment), Paper & Pulp, Food & Beverages, Metals & Mining, Others. The chemicals & petrochemicals segment leads, driven by high-quality steam demands.

-

By Technology: Condensing boilers and Non-condensing boilers. Condensing boilers increasingly preferred due to efficiency gains.

-

By Fuel: Natural Gas, Oil, Coal, Others. The natural gas segment leads due to lower CO₂ emissions and regulatory preference.

-

By Region: North America, Europe, Asia-Pacific, Middle East & Africa, South America. Asia-Pacific is fastest growing; Europe had a large share in earlier years

This segmentation helps stakeholders identify where to focus: e.g., water-tube + condensing + natural-gas boilers in chemicals & petrochemicals in Asia-Pacific represent high-potential slices.

Country-Level Analysis for USA & Germany

-

United States (USA): As a mature market within North America, the U.S. benefits from high industrial base, stringent emission regulations and retrofit demand for older boiler fleets — providing stable demand for efficient boiler systems, services and upgrades.

-

Germany: As a leading industrial economy in Europe, Germany exemplifies demand for advanced, high‐quality boiler systems, energy-efficiency upgrades, fuel transitions and regulatory compliance. Germany’s industrial heavy-machinery sector and export-oriented manufacturing make it a key country-level reference point in this market.

These country-level insights underscore that while growth may be higher in emerging markets, mature markets like USA and Germany remain important for high‐value, efficient boiler solutions and service ecosystems.

Commutator (Consumer/User) Analysis

From the perspective of the “commutator” — the end user, which in this market includes industrial facility owners, boiler system integrators, maintenance providers, process-industry engineers — the following apply:

-

Industrial operators require boilers that deliver reliable steam/heat, high uptime, predictable maintenance, efficiency (to control fuel costs) and compliance with emissions/standards.

-

Procurement & maintenance teams face pressure to reduce lifecycle cost, choose fuel‐flexible options, integrate monitoring/diagnostic services and ensure retrofit capability in older plants.

-

Service providers/rental companies see opportunity in providing maintenance, refit, monitoring, retrofit upgrades and parts‐services, as boilers become longer in service and subject to upgrade rather than replacement.

-

Challenges for end‐users include high initial capital investment, installation/logistical complexity (transporting large equipment, installation downtime), training for operators, and balancing the choice of fuel/technology given regulatory/fuel-cost uncertainty (e.g., coal vs natural gas vs biomass). The report mentions these constraints as growth inhibitors.

Thus, from a user‐perspective, system reliability, efficiency, cost control, service support and regulatory compliance matter as much as the upfront equipment purchase.

Press Release Conclusion

In summary, the global industrial boiler market is on a growth trajectory — from approximately USD 35.60 billion in 2024 to around USD 55.31 billion by 2032 (CAGR ~5.66%). Growth is underpinned by robust drivers such as industrial expansion, demand for efficient steam/heat systems, stricter emissions/regulations and fuel-transition dynamics. Segmentation by type (water-tube vs fire-tube), technology (condensing), fuel (natural gas) and end-use (chemicals & petrochemicals) provides clear direction for manufacturers, service providers and investors. Country-level insights (USA, Germany) highlight how mature markets support high-value, efficient solutions, while emerging regions provide volume growth. For equipment buyers and facility operators, focus lies in lifecycle cost, fuel flexibility, serviceability and compliance. For manufacturers, integration of intelligent controls, fuel-efficient designs, modular systems and service-offerings will be key to capturing value. The industrial boiler market is not just expanding—it is evolving. Stakeholders who adapt to efficiency demands, fuel transitions and service innovations will lead in the next era of industrial steam generation.

About us