How to Choose the Right Stainless Steel Fittings in Australia

Whether it's related to residential plumbing, commercial endeavours, or industrial applications, selecting the right fittings is imperative for any piping system. Quality fittings provide reliable connections, eliminate leaks, and promote long service life of pipelines. The replacement of fittings made with materials that are less durable and corrodible has been on the rise in Australia, predominantly in the water management, plumbing, and PEX fittings sectors, thereby rendering stainless steel the component of choice among the professionals.

What are Stainless Steel Fittings?

Stainless steel fittings Australia are specifically designed plumbing components that facilitate connections, or redirect and seal capabilities for different pipes in various systems. These fittings provide huge advantages in durability and corrosion resistance, as well as usability across a vast range of applications. Europress is a leading supplier in Australia specific to certified stainless steel fittings that comply with relevant industry product standards and promote performance and safety for projects of all sizes.

Benefits of Stainless Steel Fittings

Using stainless steel fittings comes with an array of benefits, such as:

-

Corrosion and rust resistance: Thus fittings can be applied to water, gas, and also chemical mix applications without a problem.

-

High strength and durability: This feature allows them to operate safely in high-pressure systems as well as heavy-duty industrial environments.

-

Temperature and pressure resistance: Stainless steel is the material, which indeed would be relied upon in extreme temperature and pressure conditions.

-

Lower maintenance: Generally, fittings have a longer life span, so you will be replacing fittings less often.

-

Adherence to standards: These comply with the Australian standards regarding health, safety as well as quality.

In conclusion, these factors contribute to the cost-effectiveness and dependability of stainless steel fittings for a robust piping project.

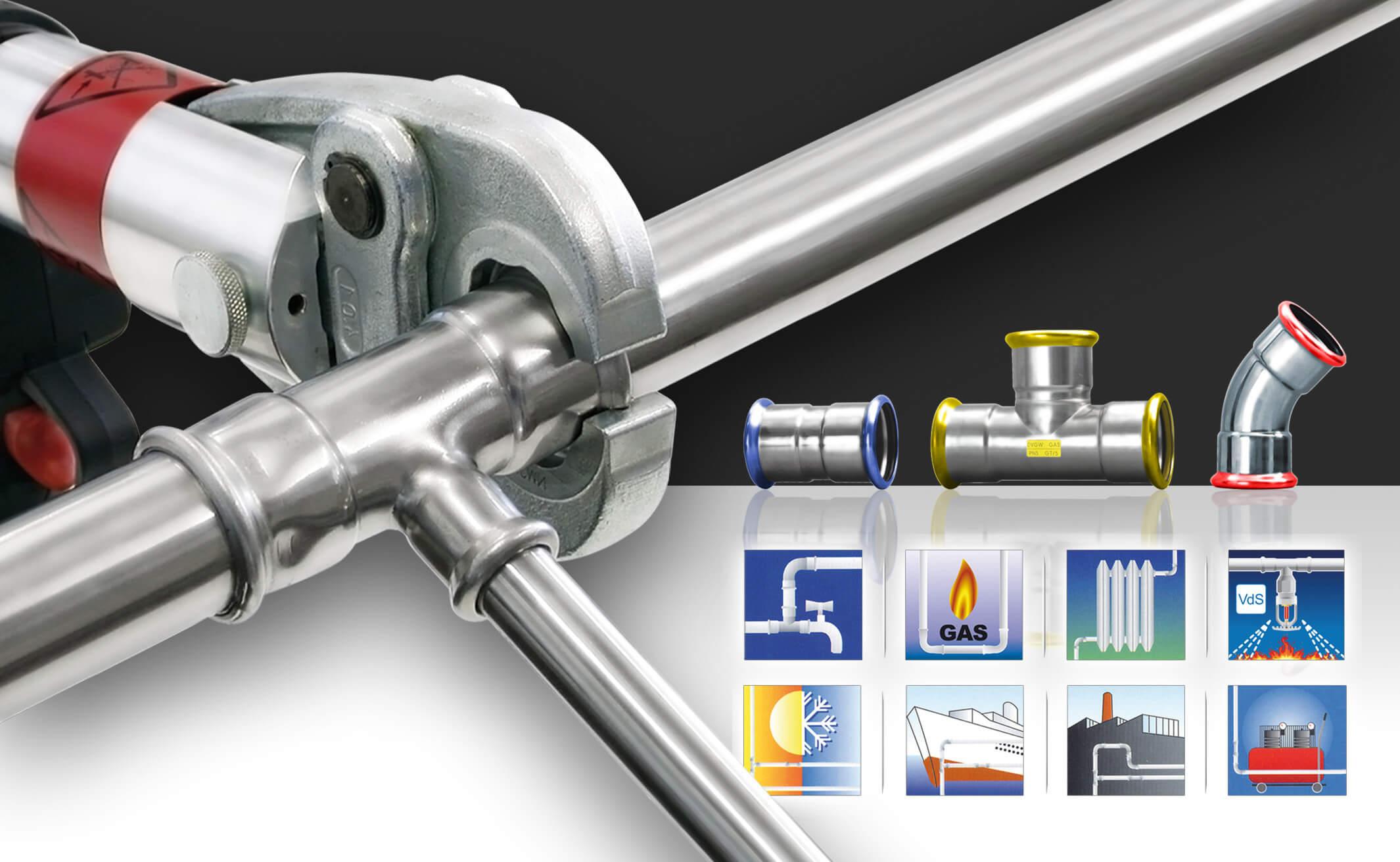

Types of Stainless Steel Fittings

Stainless steel fittings come in many types of industrial-grade fittings:

-

Elbows (45° and 90°): Redirect flow safely and effectively.

-

Tees and Crosses: Split or combine flow in the pipeline.

-

Couplings and Unions: Join two pipes together, whether they are the same or varying sizes.

-

Reducers and Adapters: These help each pipe size to fit together for ease of installation.

-

End Caps and Flanges: These are used to seal end pipe openings or provide removable joints.

-

Specialty Fittings: Used for industrial applications, internal, high-pressure applications, or projects that require custom prospective standards.

Europress supplies a full range of these fittings to meet your project specifications.

Industries that Utilize Stainless Steel Fittings

Stainless steel fittings are utilized in many applications including:

-

Residential Plumbing: For hot and cold water systems and heating systems

-

Commercial Buildings: For utility piping areas, including kitchens and bathrooms

-

Industrial Facilities: Utilizing fittings in factories, plants, and chemical processing piping

-

HVAC Systems: Utilizing fittings for heating, ventilation, and cooling pipelines

-

Food and Beverage Processing: Fittings in hygienic systems for safe liquid transfer

The versatility and reliability of stainless steel fittings lend themselves to almost any piping application.

Stainless Steel Fittings vs Other Materials

In comparison with other materials, such as copper, brass, or PVC, stainless steel fittings have advantages:

-

Superior corrosion resistance and chemical resistance

-

Greater strength and capable of handling high pressures

-

Greater longevity and requires less maintenance

-

Compatibility with a wider range of systems

Europress assists in determining the best material and design for each application, while ensuring optimal function and safety.

Best Practices for Installation

To maximize efficiency and longevity of stainless steel fittings:

-

Prepare all pipes and fittings properly to prevent and debris and ensure a clean connection

-

Utilize manufacturer recommended tools and installation procedures

-

Align fittings accurately to avoid creating stress on the fittings which will cause leaks

-

Conduct a pressure test after installation to ensure the system is secured

Following these practices will lead to pipelines will be leak free and endure in service longer.

Selecting the Proper Stainless Steel Pipe Fittings

There are a couple of factors that play an important role in making the right decision for pipe fittings:

-

The application: Water, gas, industrial

-

The grade of the material and its compatibility with the pipes

-

Compliance with the Australian code

-

Moreover, it is necessary to seek a trustworthy supplier, such as Europress, for the sake of your business. Acquiring first-rate fittings from a trusted supplier is to take out safety, efficacy, and reliability from the very beginning and for many years to come.

Conclusion

For all of the above reasons, stainless steel pipe fittings are the top pick in the case of durability, corrosion resistance, and performance of all kinds of piping systems, whether residential, commercial or industrial. Their capability to handle and endure widely fluctuating temperature, pressure, and chemical environments are the main reasons for being the ones that professionals turn to. Europress is a front-runner in the supply of certified high-quality stainless steel pipe fittings that guarantee safe, efficient, and reliable pipelines for many years. Thus, buying high-quality fittings is a good way to help your investment, minimize maintenance costs, and keep the system trustworthy and efficient for longer periods.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness