What Causes Turbine Flow Meter Readings to Fluctuate or Become Inaccurate?

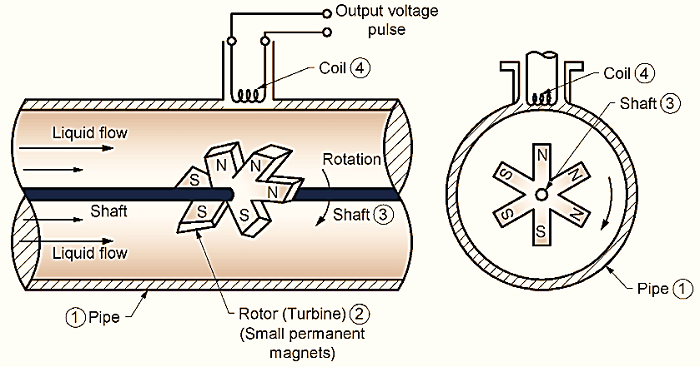

Turbine flow meters are widely used in industries to measure the flow rate of liquids and gases. They operate by using a rotor that spins as fluid passes through the meter. The rotational speed of the rotor is proportional to the flow rate. While turbine flow meters are generally reliable, their readings can fluctuate or become inaccurate under certain conditions. Understanding these causes is essential for maintaining precise measurements and ensuring safe, efficient operations. Interestingly, some cinematic examples can help illustrate these technical concepts.

Mechanical and Operational Factors

Rotor Wear and Damage

One major cause of inaccurate readings in a turbine flow meter is rotor wear. Over time, the rotor blades can degrade due to friction, cavitation, or abrasive particles in the fluid. This wear changes the rotor’s responsiveness, leading to either higher or lower readings than the actual flow.

In films, we often see machines or vehicles fail because of wear and tear. For instance, in Apollo 13, the engineers have to adjust their instruments to account for worn components in spacecraft systems. Similarly, in a turbine flow meter, worn rotors must be replaced or recalibrated to maintain accuracy. Failure to address rotor wear can lead to prolonged misreadings.

Improper Installation

Another key factor is installation. Turbine flow meters require straight runs of pipe before and after the meter to ensure laminar flow. If the meter is installed near bends, valves, or pumps without adequate straight pipe lengths, turbulent flow can occur. This turbulence disrupts the rotor’s motion, causing fluctuating readings.

Films often dramatize turbulence in engines or fluid systems. In The Martian, for example, Mark Watney faces challenges managing fluid distribution in a confined system. The movie illustrates how irregular flow can disrupt machinery operation. In the same way, improper installation of a turbine flow meter can compromise its ability to accurately measure flow.

Fluid Properties Affecting Accuracy

Viscosity and Density Variations

The viscosity and density of the fluid have a significant impact on turbine flow meter performance. High-viscosity fluids resist rotor movement, while low-viscosity fluids may cause overspeeding of the rotor. Similarly, changes in fluid density alter the kinetic energy impacting the rotor, affecting measurement accuracy.

In cinematic terms, consider Gravity, where the behavior of oxygen and other gases must be carefully monitored to sustain life. Variations in properties can lead to critical miscalculations. Likewise, in turbine flow meters, ignoring viscosity and density can produce fluctuating readings or errors in flow calculation.

Air Bubbles and Gas Entrainment

Air bubbles or gas pockets in the fluid can disrupt turbine flow meter readings. As bubbles pass the rotor, they cause sudden changes in rotor speed. These fluctuations are interpreted as variations in flow rate, resulting in inaccurate measurements.

An example from film is the submarine scenes in The Hunt for Red October, where the presence of air or gas in the water column affects sonar readings. Similarly, air in a fluid stream can distort the measurement signal of a turbine flow meter, highlighting the importance of degassing liquids before measurement.

External Influences on Meter Performance

Temperature and Pressure Changes

Turbine flow meters are sensitive to temperature and pressure variations. Extreme temperatures can expand or contract the rotor or housing, altering tolerances. Pressure fluctuations can change flow characteristics, affecting rotor response.

Movies often depict high-stakes situations involving extreme temperatures or pressure. In Titanic, for instance, the freezing water and pressure changes challenge machinery operation. These cinematic examples reflect the real-world challenges turbine flow meters face. Without proper temperature and pressure compensation, readings can fluctuate significantly.

Electromagnetic Interference

Modern turbine flow meters often include electronic sensors to detect rotor movement. These sensors can be affected by electromagnetic interference (EMI) from nearby motors, radio signals, or power lines. EMI can generate false pulses or disrupt signal processing, leading to inaccurate readings.

In films like Iron Man, electronics in suits can be affected by electromagnetic sources. Similarly, turbine flow meters must be shielded and grounded properly to ensure electronic components do not produce spurious readings.

Maintenance and Calibration Issues

Neglecting Regular Calibration

Turbine flow meters require periodic calibration to maintain accuracy. Over time, mechanical wear, environmental conditions, or fluid contamination can alter performance. Failure to recalibrate results in drift, causing the readings to become unreliable.

Films often illustrate the consequences of neglecting maintenance. In Jurassic Park, neglected systems create chaos. Likewise, ignoring turbine flow meter calibration leads to misreadings that can have serious operational or safety consequences.

Contamination and Debris

Particles, sediment, or debris in the fluid can lodge between rotor blades or interfere with the sensor mechanism. This contamination can slow the rotor, obstruct smooth rotation, or produce erratic signals.

A cinematic analogy is seen in The Abyss, where debris in the underwater system interferes with machinery. In turbine flow meters, even small contaminants can significantly impact accuracy. Regular cleaning and filtration are essential to prevent this type of error.

Signal Processing and Electronics

Noise in Output Signals

The electronic output from a turbine flow meter may contain noise, especially in high-flow or turbulent conditions. This noise can create false readings or spikes, which appear as fluctuating flow rates. Advanced signal processing and filtering are necessary to extract true flow data.

In film, control room sequences often show operators distinguishing signal from noise under extreme conditions. In the same way, turbine flow meter systems must use proper electronics to distinguish true rotor signals from environmental interference.

Faulty Wiring or Connections

Electrical connections can degrade over time or become loose. A faulty sensor wire can generate intermittent signals, mimicking fluctuating flow. These errors are not mechanical but electronic, yet they still cause the meter to display inconsistent readings.

An example in cinema is the spacecraft control systems in Interstellar, where loose connections can create false readings and critical errors. Turbine flow meters face similar risks if wiring and electronic contacts are not properly maintained.

Conclusion

Turbine flow meter readings can fluctuate or become inaccurate due to mechanical issues, improper installation, fluid properties, environmental factors, maintenance neglect, and electronic interference. Rotor wear, turbulence, viscosity variations, and gas entrainment all impact mechanical operation. Temperature, pressure, and electromagnetic fields influence performance externally. Calibration and contamination are critical for long-term accuracy. Electronic signal noise and wiring faults can also introduce errors.

Film examples, such as Apollo 13, The Pursuit of Happyness, Gravity, and The Abyss, illustrate parallels between real-world mechanical challenges and cinematic scenarios, making it easier to understand turbine flow meter behavior. By recognizing these factors and applying proper maintenance, calibration, and installation practices, industries can maximize reliability and ensure that turbine flow meters provide accurate, consistent flow measurements over time.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness