Comparing Different Printing Techniques for Custom Display Boxes

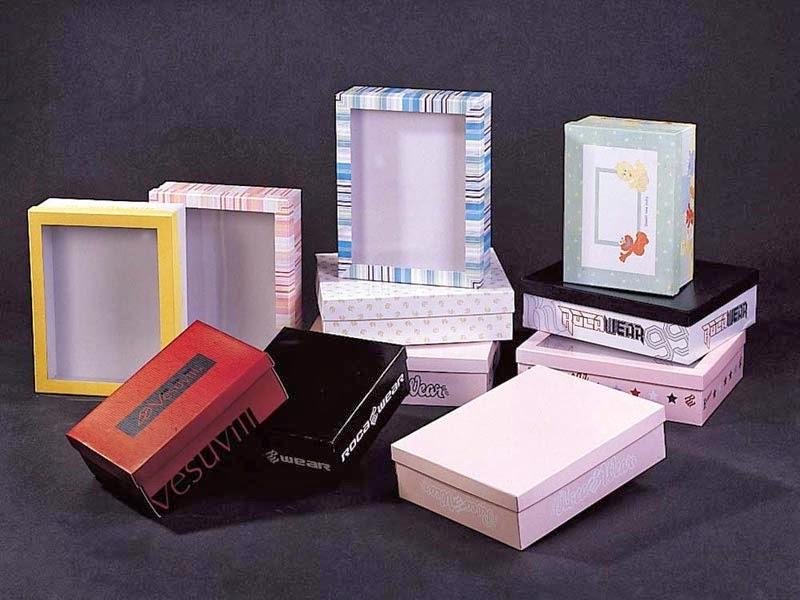

Creating attractive packaging is essential for brands today. One powerful tool that helps products stand out on shelves is the custom display box. Choosing the right printing method is just as important as the design itself. Each printing technique offers different benefits, costs, and effects. Understanding these can help businesses make better decisions for their product packaging needs.

Offset Printing: High-Quality and Cost-Effective for Large Runs

Offset printing is one of the most common techniques used in packaging for custom display boxes. It provides sharp, clean images with consistent colors. This method works by transferring ink from a plate to a rubber blanket and then onto the surface. It is best suited for printing large quantities.

The biggest advantage of offset printing is its excellent image quality. The process supports full-color printing and allows fine details to be visible. This is ideal when trying to showcase complex graphics or detailed logos.

Another strength of offset printing is its efficiency with bulk orders. Once the plates are prepared, it becomes very affordable to print thousands of boxes. This makes it a favorite for large businesses or seasonal campaigns that require mass production.

Despite the upfront costs of making printing plates, the long-term savings are clear for large runs. Additionally, there are many materials that can be used in this method, including cardboard and paperboard. These are common in retail packaging.

On the downside, offset printing may not be the best for small orders. It takes time to set up, so the cost is not justified for a few pieces. Also, changes to the design after the plate is made can be costly.

Overall, for companies looking for quality and volume, offset printing is an excellent choice. It delivers a professional look that enhances the appearance of packaging and supports brand image.

Digital Printing: Flexible and Perfect for Small Batches

Digital printing is a modern method that works directly from digital files. It skips the need for printing plates, making it much faster to set up. This technique is especially useful for small orders or short-run packaging projects.

One of the key advantages of digital printing is flexibility. Businesses can change designs quickly without extra setup costs. This is helpful for test marketing or personalized packaging. It also makes it easier to print boxes with unique serial numbers or customer names.

Another benefit is the speed of production. Since there are no plates to prepare, orders can be fulfilled in a shorter time. This is perfect for businesses that need fast turnaround or last-minute changes.

Digital printing also offers excellent print quality. The colors are vibrant, and the results are consistent. While it may not match the fine detail of offset printing, it is more than enough for most packaging needs.

The main downside is the higher cost per unit when printing large amounts. Unlike offset, digital printing does not get cheaper with higher volumes. However, for small batches, it is often the most economical choice.

In conclusion, digital printing is ideal for businesses that value speed, flexibility, and lower setup costs. It is perfect for startups or niche products that do not require mass production. While it may not be the cheapest for big orders, its benefits make it highly valuable in many packaging projects.

Flexographic Printing: Great for Simple Designs and Large Runs

Flexographic printing is widely used in the packaging industry. It uses flexible plates and fast-drying inks to print on different surfaces. This method works well for both paper and plastic materials, making it suitable for many packaging types.

One of the strongest features of flexographic printing is speed. It allows for fast production with high output. This makes it ideal for large-scale packaging needs, especially when the design is simple and doesn't need photo-quality detail.

The setup cost can be high due to the need for custom plates. However, the cost per unit drops as the quantity increases. That’s why many companies use flexography for standard packaging designs repeated in bulk.

Flexographic printing is also known for its ability to handle various types of inks, including water-based and UV inks. These inks dry quickly, allowing for fast turnaround and packaging efficiency. It's an eco-friendly option when used with water-based inks.

The quality of printing may not match digital or offset printing for complex designs. Flexography is better suited for solid colors, simple graphics, and text-heavy layouts. If the packaging does not require gradients or high-resolution images, this method performs well.

In terms of versatility, flexographic printing can work on corrugated boards, plastic films, and even foil. This gives packaging designers more options when selecting materials.

Overall, flexographic printing is a smart choice for companies needing large runs with straightforward designs. It combines speed, versatility, and cost savings, especially when used consistently.

Screen Printing: Ideal for Bold Colors and Textures

Screen printing is a traditional method known for its bold, rich colors. It uses a mesh screen to apply ink directly to the surface. Each color in the design has its own screen, making it more suited to designs with fewer colors.

One major benefit of screen printing is its ability to create textured, tactile effects. It adds a layer of ink that stands out, both visually and by touch. This is especially appealing for packaging that aims to give a luxurious or handcrafted feel.

This method is also great for producing bright, solid colors. It offers strong visual impact and can be used on various materials like cardboard, plastics, and metals. It is also good for darker surfaces where other techniques might fail to show vibrant colors.

However, screen printing is not ideal for detailed images or small text. The resolution is lower compared to digital or offset printing. Also, the process is slower and more labor-intensive, making it better for special editions or limited runs.

Setting up screen printing involves creating a new screen for each color. This adds time and cost to the process. But for brands that want to make their packaging pop with bold visuals, screen printing offers a unique edge.

Screen printing works well for brands that focus on visual identity and experience. It’s a great tool for building premium product presentations, especially when the product itself is artisanal or high-end.

Gravure Printing: Precision and Durability for Premium Packaging

Gravure printing is one of the highest-quality printing methods available. It involves etching the design onto a metal cylinder. Ink is applied, and excess is wiped off, leaving ink only in the etched areas. The result is a sharp and clean image.

One of the main benefits of gravure printing is consistency. It delivers the same results every time, even in large volumes. This is important for luxury or premium products where packaging must look perfect.

Gravure printing is also very durable. The etched cylinders can be used for millions of prints, making it cost-effective for high-volume orders. This durability ensures uniform quality over time.

The detail and color depth it offers are unmatched. Gradients, shadows, and tiny text appear clearly. This makes it ideal for high-end packaging that demands perfect reproduction of a brand’s design.

However, gravure printing is expensive to set up. The cost of making the engraved cylinders is high. It’s not a good choice for small batches or short-term projects. Also, it works best on smooth, flat surfaces.

Despite its costs, gravure printing is worth the investment for brands that want to deliver a premium experience. It combines visual appeal with printing strength. It's especially popular in cosmetic, perfume, and luxury food packaging.

UV Printing: Instant Drying with Strong Visual Impact

UV printing uses ultraviolet light to cure or dry the ink as it is printed. This instant drying process prevents smudging and enhances sharpness. It allows printing on almost any surface, including glass, plastic, and metal.

One of the key strengths of UV printing is its durability. The cured ink is resistant to scratches, water, and fading. This makes it a great choice for packaging exposed to light or moisture.

Another advantage is its ability to produce high-resolution images with strong color contrast. The results are visually striking, which is helpful in catching consumer attention on store shelves. It also allows for the use of glossy, matte, or textured finishes.

UV printing supports environmental safety too. It does not use solvents that evaporate into the air. This makes it a more eco-friendly solution compared to some older methods.

The speed of UV printing is also notable. Since the ink dries immediately, production times are shorter. This is helpful for meeting tight deadlines or quick product rollouts.

One limitation is the cost. UV printing equipment and materials are more expensive. However, for small to medium runs where quality matters, it provides good value.

UV printing is suitable for brands looking for vibrant, lasting results. It's also ideal for printing on unique packaging surfaces that traditional methods can't handle well.

Eco-Friendly Printing Options for Sustainable Brands

As consumers become more eco-conscious, brands must look for green printing solutions. There are several techniques and materials that support this goal while still offering quality and appeal.

Water-based inks are one of the top choices. They are free of harmful chemicals and reduce air pollution during printing. These inks also perform well in flexographic and digital printing methods.

Soy-based inks are another popular choice. They are made from natural soy oil and break down more easily than petroleum-based inks. These inks work especially well with paper packaging and maintain bright, clear colors.

Using recycled materials for packaging also reduces environmental impact. Many printers now offer recycled paperboard that works with various printing methods. This is especially useful for businesses that want to promote a green image.

Additionally, some printing processes, like digital printing, produce less waste and use less energy. They eliminate the need for plates, reducing the use of materials and chemicals.

For sustainable packaging, brands should also look into vegetable-based coatings and adhesives. These options complete the eco-friendly package and support safe disposal or recycling.

In the long run, choosing green printing techniques not only helps the planet but also builds customer trust. Eco-conscious consumers are more likely to support brands that care about the environment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness