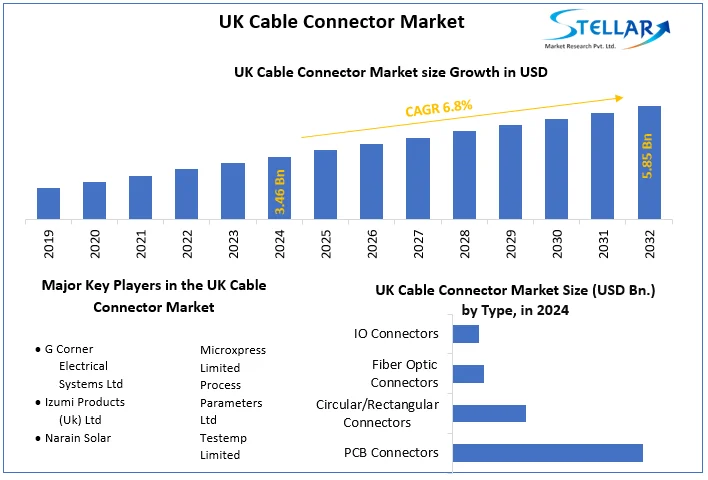

UK Cable Connector Market Size To Grow At A CAGR Of 6.8% In The Forecast Period Of 2025-2032

UK Cable Connector Market: Connectivity Underpins the UK’s Digital Backbone

1. Market Estimation & Definition

The UK cable connector market was valued at US$ 3.46 billion in 2024 and is projected to grow to approximately US$ 5.85 billion by 2032, representing a compound annual growth rate (CAGR) of about 6.8% over the period 2025-2032.

Cable connectors refer to mechanical and electrical devices used to join cables, assemblies, wires and related components, enabling transmission of power, data, signal or control. In the UK context this covers connectors used in fibre-optic networks, telecommunications, automotive wiring harnesses, power & signal cables in industrial settings, aerospace & defence, and consumer electronics. According to the findings, growth is being driven by increasing urbanisation, expansions in telecommunications networks, rising electronics use and adoption of automation across industries

Request Free Sample Report:

https://www.stellarmr.com/report/req_sample/UK-Cable-Connector-Market/117

2. Market Growth Drivers & Opportunities

Several factors are fueling the UK cable connector market’s expansion and present clear opportunities:

Telecommunications network expansion and data-infrastructure investment: The UK government’s drive toward gigabit broadband and full fibre deployments is boosting demand for fibre-optic cable connectors. The report notes that the fibre optics cable product segment is expected to grow at a high rate – a CAGR of 12.7% over the forecast period.

Growth in consumer electronics and connected devices: As more homes adopt smart devices, IoT sensors, and home automation, the need for reliable cable connectors in routers, set-top boxes, gaming consoles and consumer electronics increases.

Automotive electrification and wiring harness complexity: UK automotive is shifting toward advanced wiring architectures for EVs and ADAS systems; this drives

Industrial automation, manufacturing and defence sectors: The UK has a strong manufacturing base and high-technology defence/aerospace industries that require precision connectors for harsh conditions, submarine/satellite systems and offshore infrastructure. The report mentions submarine/satellite connectors need to meet tough environmental demands.

Urbanisation & infrastructural upgrades: As the UK invests in smart city infrastructure, data centres, 5G rollout and renewable energy installations, the underlying cable connector market indirectly benefits via higher volumes of cabling, signal and power systems.

These drivers reflect both volume expansion (more units) and value growth (higher-performance connectors) — critical for suppliers seeking margin growth.

In a world where connectivity is the backbone of commerce and infrastructure, cable connectors are the unsung enablers. The UK market offers several clear growth segments—particularly in telecom/fibre-optic, automotive wiring and industrial systems. Stakeholders who align with these growth areas, adopt advanced technologies, and emphasise innovation and service will capture the upside. While competitive pressures and cost dynamics remain, the overall trajectory is favourable — making the UK connector market an attractive space for investment, innovation and strategic growth.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

[email protected]UK Cable Connector Market Size To Grow At A CAGR Of 6.8% In The Forecast Period Of 2025-2032

UK Cable Connector Market: Connectivity Underpins the UK’s Digital Backbone

1. Market Estimation & Definition

The UK cable connector market was valued at US$ 3.46 billion in 2024 and is projected to grow to approximately US$ 5.85 billion by 2032, representing a compound annual growth rate (CAGR) of about 6.8% over the period 2025-2032.

Cable connectors refer to mechanical and electrical devices used to join cables, assemblies, wires and related components, enabling transmission of power, data, signal or control. In the UK context this covers connectors used in fibre-optic networks, telecommunications, automotive wiring harnesses, power & signal cables in industrial settings, aerospace & defence, and consumer electronics. According to the findings, growth is being driven by increasing urbanisation, expansions in telecommunications networks, rising electronics use and adoption of automation across industries

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/UK-Cable-Connector-Market/117

2. Market Growth Drivers & Opportunities

Several factors are fueling the UK cable connector market’s expansion and present clear opportunities:

Telecommunications network expansion and data-infrastructure investment: The UK government’s drive toward gigabit broadband and full fibre deployments is boosting demand for fibre-optic cable connectors. The report notes that the fibre optics cable product segment is expected to grow at a high rate – a CAGR of 12.7% over the forecast period.

Growth in consumer electronics and connected devices: As more homes adopt smart devices, IoT sensors, and home automation, the need for reliable cable connectors in routers, set-top boxes, gaming consoles and consumer electronics increases.

Automotive electrification and wiring harness complexity: UK automotive is shifting toward advanced wiring architectures for EVs and ADAS systems; this drives

Industrial automation, manufacturing and defence sectors: The UK has a strong manufacturing base and high-technology defence/aerospace industries that require precision connectors for harsh conditions, submarine/satellite systems and offshore infrastructure. The report mentions submarine/satellite connectors need to meet tough environmental demands.

Urbanisation & infrastructural upgrades: As the UK invests in smart city infrastructure, data centres, 5G rollout and renewable energy installations, the underlying cable connector market indirectly benefits via higher volumes of cabling, signal and power systems.

These drivers reflect both volume expansion (more units) and value growth (higher-performance connectors) — critical for suppliers seeking margin growth.

In a world where connectivity is the backbone of commerce and infrastructure, cable connectors are the unsung enablers. The UK market offers several clear growth segments—particularly in telecom/fibre-optic, automotive wiring and industrial systems. Stakeholders who align with these growth areas, adopt advanced technologies, and emphasise innovation and service will capture the upside. While competitive pressures and cost dynamics remain, the overall trajectory is favourable — making the UK connector market an attractive space for investment, innovation and strategic growth.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

[email protected]